The Evolution of Global Piglet Feeders: From Basic Tools to Automated Feeding Equipment

From rudimentary stone and wooden troughs to precision smart automated feeding systems, the evolution of global piglet feeders is an epic tale of the livestock industry’s transformation toward efficiency, precision, and intelligence. Every upgrade directly addresses the core pain points of farmers; every innovation injects new momentum into large-scale breeding operations. Today, this decades-long evolution has completely reshaped the feeding logic of the global pig farming industry, ushering in a new era where "experience-based pig farming" transitions to "data-driven pig farming".

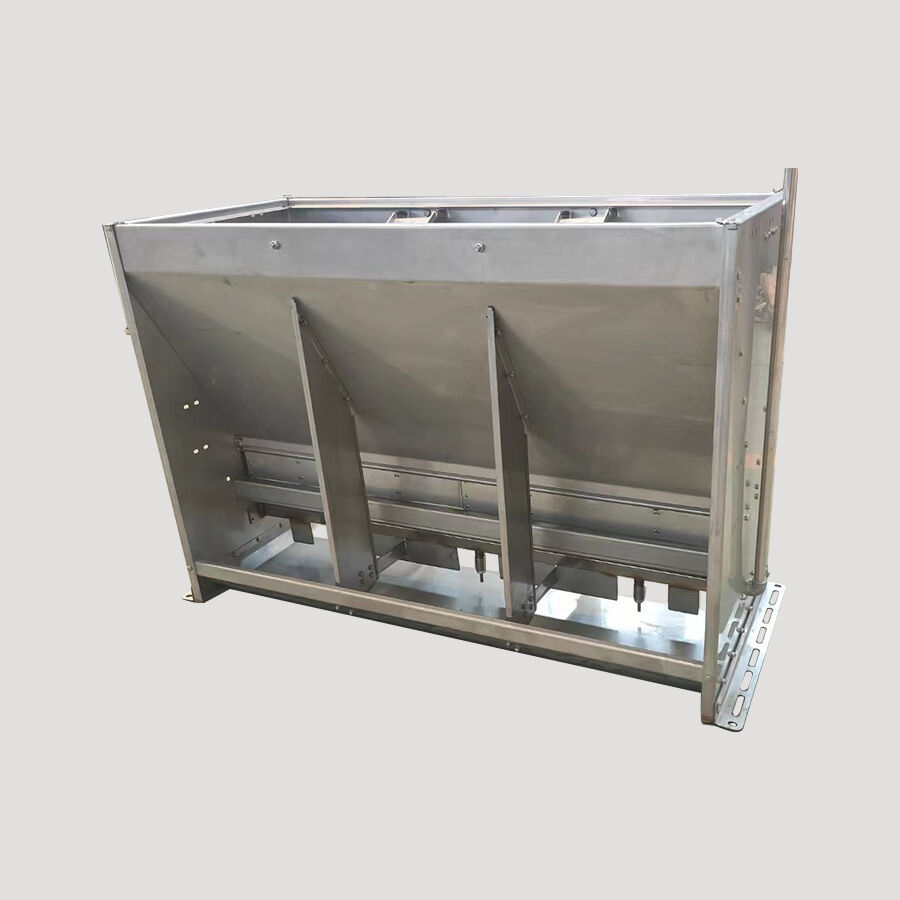

Early feeders merely fulfilled the basic need of "providing a place to feed". Cement and iron sheet troughs were bulky and hard to clean, resulting in severe feed waste. Uneven feeding among piglets led to significant growth disparities, becoming the first bottleneck restricting breeding efficiency. With the rise of large-scale farming, the second generation of feeders underwent material and structural innovations: food-grade engineering plastics and stainless steel replaced traditional materials, offering aging resistance, corrosion resistance, and easy cleaning. Wall-mounted and split-type designs saved space, while adjustable feeding volume structures initially reduced feed waste. These improvements transformed feeders from "basic tools" into "practical equipment", perfectly catering to the core needs of small and medium-sized farms.

As breeding scales expanded further, rising labor costs and insufficient feeding precision emerged as new industry pain points, propelling feeders into the era of the "automation revolution". Designs such as automatic feeding and large-capacity hoppers came into being, allowing one refill to meet 1–2 days of feeding demands and significantly cutting down labor input. Humanized structures like dry-wet separation and urine-proof design eliminated feed mold and waste at the source, maintaining a cleaner breeding environment. The core of this evolutionary phase was "freeing up hands", enabling farmers to shift their focus from tedious daily feeding tasks to pig herd health management.

Just a quick question—what does your ideal pig farm feeding environment look like?