Коррозионностойкие свинские станки горячего цинкования с повышенной прочностью и индивидуальными размерами представляют собой передовое решение для современных сельскохозяйственных предприятий, которым требуются надежные и долговечные системы содержания животных, способные выдерживать сложные условия интенсивного свиноводства. Эти специализированные сельскохозяйственные загоны изготавливаются с применением передовых технологий горячего цинкования, создающих прочное защитное покрытие, обеспечивающее исключительную устойчивость к коррозии, влаге и агрессивным химическим веществам, которые часто встречаются на объектах свиноводства. Процесс цинкования заключается в погружении стального каркаса в расплавленный цинк, в результате чего образуется металлическая связь, проникающая глубоко в поверхность металла, обеспечивая всестороннюю защиту, превосходящую обычные поверхностные покрытия. Такой производственный подход позволяет свиным станкам сохранять свою конструктивную целостность и внешний вид даже при постоянном воздействии влажности, паров аммиака и частой мойке дезинфицирующими растворами. Повышенная долговечность делает эти изделия особенно подходящими для коммерческого свиноводства, племенных хозяйств и сельскохозяйственных предприятий, которым требуется стабильная работа в течение длительных периодов эксплуатации. Возможность индивидуальной настройки является ключевой особенностью таких станков, позволяя специалистам точно определять размеры, конфигурации и характеристики, соответствующие планировке помещений, требованиям по благополучию животных и операционным процессам. Гибкость в выборе габаритов обеспечивает беспрепятственную интеграцию в существующие конструкции помещений, оптимальное использование пространства и поддержание соответствующей плотности размещения животных. Профессиональные производственные команды тесно сотрудничают со специалистами в области сельского хозяйства, чтобы разрабатывать конструкции, отвечающие конкретным программам разведения, фазам роста и протоколам управления, гарантируя, что каждая установка способствует оптимальному здоровью животных и высокой продуктивности. Конструкция предусматривает тщательно рассчитанные промежутки между прутьями, усиленные угловые соединения и стратегически расположенные зоны кормления, облегчающие повседневные операции и обеспечивающие безопасность и комфорт животных. Технология отделки поверхности выходит за рамки базового цинкования и включает дополнительные обработки, повышающие гладкость, снижающие накопление бактерий и упрощающие очистку, что способствует повышению стандартов гигиены на всем объекте. Эти методы также минимизируют острые края и шероховатые поверхности, которые могут травмировать животных или обслуживающий персонал во время регулярного технического обслуживания. Производственная философия делает акцент на стабильности качества на всех этапах производства, гарантируя, что сельскохозяйственные предприятия могут рассчитывать на единообразные эксплуатационные характеристики независимо от объема заказа или степени индивидуализации. Международные закупочные команды ценят сотрудничество с производителями, понимающими глобальные сельскохозяйственные стандарты и способными адаптировать свои производственные процессы под различные нормативные требования разных рынков. Аспекты, связанные с экспортом, учитываются на всех этапах производства и упаковки, с особым вниманием к мерам защиты, предотвращающим повреждение продукции при транспортировке на дальние расстояния и обеспечивающим поставку изделий в идеальном состоянии. Модульный подход к проектированию позволяет эффективно упаковывать продукцию, максимально используя вместимость транспортных контейнеров и снижая расходы на перевозку для международных покупателей. Протоколы обеспечения качества включают несколько этапов проверки — от подтверждения качества сырья до тестирования готовых изделий, гарантируя, что каждый свинской станок соответствует строгим стандартам прочности перед отправкой. Возможности для сотрудничества распространяются на комплексные партнерства OEM и ODM, при которых производители напрямую работают с дистрибьюторами сельскохозяйственной техники, компаниями по строительству ферм и проектировщиками животноводческих комплексов для разработки специализированных решений, отвечающих новым рыночным потребностям. Такие совместные отношения зачастую приводят к инновационным улучшениям конструкций и совершенствованию производственных процессов, выгодным для всего сельскохозяйственного сообщества. Универсальность индивидуальных свиных станков делает их пригодными для различных сельскохозяйственных применений помимо традиционного откорма, включая племенные хозяйства, питомники и специализированные исследовательские установки, где важна точная организация содержания животных. Экологические аспекты становятся всё более значимыми в современном сельском хозяйстве, и длительный срок службы правильно оцинкованных свиных станков способствует устойчивому ведению фермерского хозяйства за счёт снижения частоты замены и минимизации образования отходов. Свойства устойчивости к коррозии обеспечивают сохранение функциональных возможностей этих устройств в течение нескольких производственных циклов, обеспечивая отличную долгосрочную отдачу от инвестиций в сельское хозяйство. Процедуры монтажа разработаны с учетом различных конфигураций помещений — от установки на уровне пола до размещения на поднятых платформах, с системами крепления, которые можно адаптировать под различные типы оснований и конструктивные требования. Прочный метод строительства гарантирует, что свинские станки способны выдерживать динамические нагрузки, связанные с движением животных, кормлением и регулярным обслуживанием, без ущерба для своей конструктивной целостности. Требования к техническому обслуживанию сведены к минимуму благодаря тщательному выбору материалов и оптимизации конструкции, что позволяет сельскохозяйственным предприятиям сосредоточить свои ресурсы на уходе за животными, а не на обслуживании оборудования. Сочетание стандартных компонентов с настраиваемыми характеристиками обеспечивает эффективное управление запасами для дистрибьюторов и предоставляет конечным пользователям необходимую гибкость для решения конкретных операционных задач. Ожидания от долгосрочного сотрудничества с поставщиками связаны с постоянным качеством поставок, оперативной технической поддержкой и непрерывной разработкой новых продуктов, которая развивается в ногу с меняющимися методами ведения сельского хозяйства и стандартами благополучия животных.

Горячеоцинкованные секции для откорма свиней с повышенной прочностью и индивидуальными размерами

-

Горячее оцинкование – Сильное антикоррозионное покрытие для длительного использования в тяжелых фермерских условиях.

-

Прочный корпус – Металлическая рама повышенной прочности обеспечивает дополнительную силу и безопасность.

-

Настраиваемый размер – Индивидуальные размеры, подходящие для различных потребностей свиноводства.

-

Легкое обслуживание – Гладкая поверхность для легкой очистки и лучшей гигиены.

-

Оптимизированный дизайн – Обеспечивает безопасное и комфортное пространство для управления откормом свиней.

- Обзор

- ТИП

- Детали

- Рекомендуемые товары

Описание

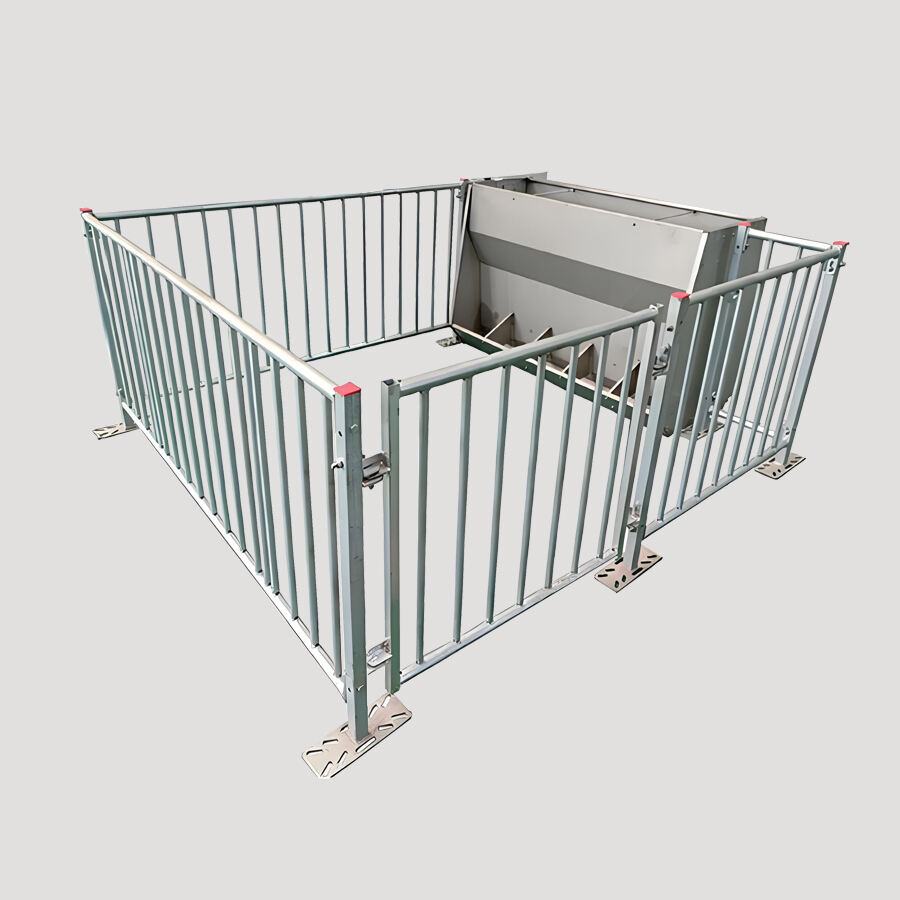

Наша клетка для содержания свиней массой более 40 кг, с покрытием методом горячего цинкования, предназначена для обеспечения прочного, гигиенического и эффективного жилища. Изготовлена с применением полного покрытия методом горячего цинкования, обеспечивает превосходную устойчивость к коррозии и долговечность, что делает ее идеальной для тяжелых условий фермерских хозяйств. Конструкция из трубчатой решетки обеспечивает прочность и устойчивость, а также безопасное и комфортное пространство для откорма свиней.

Эта клетка обладает высокой универсальностью, поддерживая различные типы кормушек для удовлетворения разнообразных потребностей в кормлении. Установка, очистка и дезинфекция выполняются легко, что способствует поддержанию здоровой и гигиенической среды для ваших свиней. Благодаря нашим вариантам настраиваемого проектирования, мы можем предоставить клетки любого размера, идеально подходящие для планировки и потребностей вашей свинофермы.

Как поставщик услуг OEM, мы также можем производить продукцию по вашим чертежам и проектам, гарантируя получение товара, соответствующего вашим конкретным требованиям. Это делает нашу комплектующую коробку отличным выбором для фермеров, ищущих сочетания прочности, гибкости и удобства.

Выберите наши комплектующие коробки, чтобы повысить эффективность фермы, обеспечить благополучие животных и упростить обслуживание вашей системы содержания свиней.

Видео с презентацией продукта

https://www.youtube.com/embed/Rjm1YVME-4M?si=YS2dnmaGFMt656_U

Сертификат

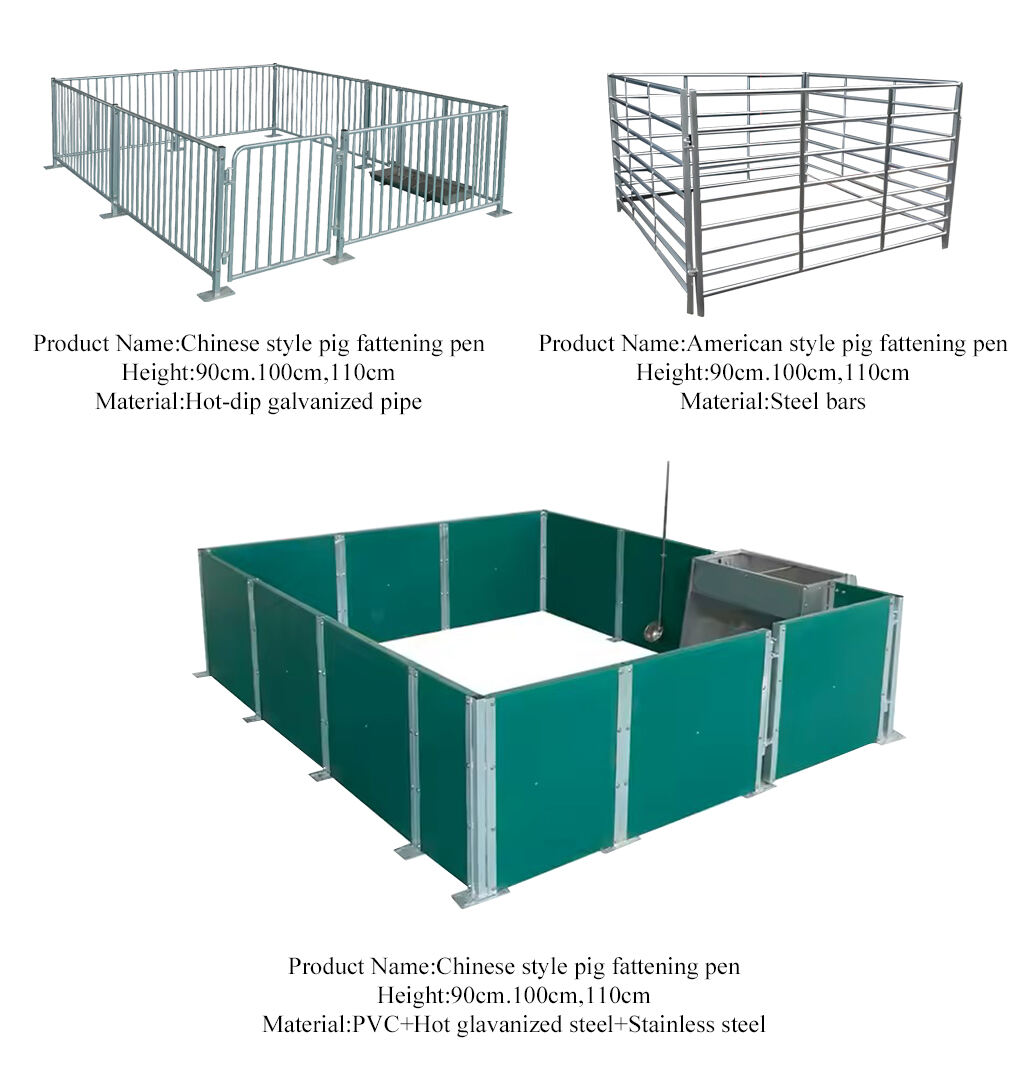

ТИП

Детали

|

Кормушка для откорма используется для кормления свиней на откорме и, как правило, проектируется индивидуально для каждой коммерческой свиньи в зависимости от различных потребностей. |

|

Утолщенные оцинкованные стальные трубы устойчивы к коррозии и не подвержены ржавчине, не деформируются при ударах |

|

|

Доступны два типа кормушек для станков откорма Кормушка из нержавеющей стали |

|

Доступны два типа кормушек для станков откорма Сушильный/влажный кормушка |

|

|

Гладкая и ровная поверхность без заусенцев, не повреждает свиней |