The Автоматический дозатор корма для откорма свиней представляет собой передовое решение для кормления, разработанное для удовлетворения высоких требований современных коммерческих свиноводческих предприятий, предоставляя международным покупателям, дистрибьюторам и специалистам по закупкам сельскохозяйственного оборудования доступ к передовым технологиям кормления, которые оптимизируют как операционную эффективность, так и стандарты благополучия животных. Эта инновационная система кормления сочетает в себе точность инженерных решений и практическую функциональность, обеспечивая комплексное решение для кормления, отвечающее сложным потребностям управления питанием на крупномасштабных объектах откорма свиней, при этом сохраняя прочность и надежность, ожидаемые в профессиональных сельскохозяйственных условиях. Двухрежимная функция кормушки позволяет плавно переключаться между сухими и влажными режимами кормления, поддерживая различные стратегии кормления, соответствующие конкретным производственным целям, сезонным колебаниям и потребностям в питательных веществах на разных этапах роста в процессе откорма. Основой данной системы кормления является высокое качество производства, включающее использование прочных конструкционных материалов, выбранных за их устойчивость к коррозионным агрессивным средам, механическим нагрузкам при непрерывной эксплуатации и воздействию жестких химических веществ, типичных для животноводческих помещений, что гарантирует стабильную работу в различных климатических условиях и при интенсивном использовании, характерном для коммерческого свиноводства. Инженерный подход делает акцент на модульных принципах проектирования, облегчающих простую установку, выполнение планового технического обслуживания и возможность расширения системы, что делает это решение особенно привлекательным для предприятий, планирующих долгосрочный рост или нуждающихся в гибкой инфраструктуре кормления, способной адаптироваться к изменяющимся производственным требованиям. Технологии поверхностной обработки, применяемые в производственном процессе, обеспечивают повышенную защиту от влаги, кислот в кормах и чистящих средств, продлевая срок службы оборудования и поддерживая гигиенические стандарты, необходимые для соблюдения требований безопасности пищевой продукции и обеспечения здоровья животных. Возможности настройки выходят за рамки стандартных конфигураций, позволяя Решения для сельскохозяйственного оборудования OEM которые можно адаптировать под конкретные планировки помещений, протоколы кормления и требования интеграции с существующими системами управления фермой, предоставляя закупочным командам возможности для разработки решений по кормлению, точно соответствующих их операционным параметрам и целям производительности. Многофункциональность дозатора делает его подходящим для различных сельскохозяйственных применений помимо традиционного откорма свиней, включая специализированные племенные хозяйства, исследовательские объекты и комплексные животноводческие комплексы, где надежная подача корма и контроль порций являются ключевыми факторами успеха. Философия стабильного качества лежит в основе каждого этапа производственного процесса — от первоначального выбора материалов до окончательной сборки и процедур испытаний, — обеспечивая соответствие каждой поставляемой единицы строгим стандартам производительности независимо от партии производства или целевого рынка, что дает международным покупателям уверенность в надежности продукции и долгосрочной эксплуатационной устойчивости. Учет требований экспорта интегрирован на всех этапах проектирования и упаковки, включая защитные меры, сохраняющие целостность продукта во время международных перевозок, хранения в различных климатических условиях и установки в разных географических регионах, при этом документация и техническая поддержка подготовлены таким образом, чтобы обеспечить беспрепятственное таможенное оформление и быстрое внедрение на целевых рынках. Подход, основанный на сотрудничестве при настройке и Партнерства по производству оригинального оборудования для кормления свидетельствует о приверженности развитию долгосрочных отношений с дистрибьюторами, системными интеграторами и конечными пользователями, обеспечивая техническую консультацию, руководство по применению и постоянную поддержку, которая выходит за рамки первоначальной поставки продукции и включает комплексную оптимизацию систем кормления и мониторинг производительности. Учет совместимости упаковки и логистики обеспечивает эффективное хранение, снижение транспортных расходов и упрощение процедур обработки на всех этапах цепочки поставок, а модульная организация компонентов упрощает управление запасами и снижает сложность для дистрибьюторов, работающих с несколькими товарными линейками или обслуживающих разнообразные рыночные сегменты. Передовые механизмы управления кормлением, встроенные в систему, позволяют точно дозировать порции, автоматизировать график кормления и внедрять протоколы сокращения потерь, что способствует повышению коэффициента конверсии корма, снижению эксплуатационных затрат и улучшению экологической устойчивости в коммерческих свиноводческих хозяйствах. Конструкция кормушки предусматривает использование материалов и производственных методов, обеспечивающих тщательную очистку и санитарную обработку — важнейшие процедуры для соблюдения стандартов биобезопасности, предотвращения распространения заболеваний и соответствия меняющимся нормам безопасности продовольствия на различных международных рынках. Ожидания от долгосрочного сотрудничества с поставщиками сосредоточены на обеспечении непрерывного технического развития, оперативной поддержки клиентов и совместного решения проблем, возникающих в области управления кормлением свиней, соблюдения нормативных требований и повышения операционной эффективности, формируя партнерские отношения, способствующие устойчивому успеху на конкурентных аграрных рынках и поддерживающие глобальное развитие эффективных и гуманных методов кормления скота.

Автоматический дозатор корма для откорма свиней

-

Конструкция с возможностью подачи сухого и влажного корма – Позволяет свиньям одновременно есть корм и пить воду, улучшая пищеварение и усвоение корма.

-

Высокая вместимость и регулировка подачи корма – Большой бункер с точной регулировкой подачи корма снижает трудозатраты и удовлетворяет потребности свиней на разных стадиях роста.

-

Прочные и гигиеничные материалы – Изготовлен из устойчивого к коррозии пластика и нержавеющей стали, легко очищается и рассчитан на длительный срок службы.

-

Эффективность кормления и водоснабжения – Экономит корм и воду за счет предотвращения их расплёскивания и загрязнения, способствует более здоровой среде кормления.

-

Идеально для группового кормления – Просторная кормушка позволяет нескольким свиньям есть одновременно, идеально подходит для интенсивных ферм по откорму.

- Обзор

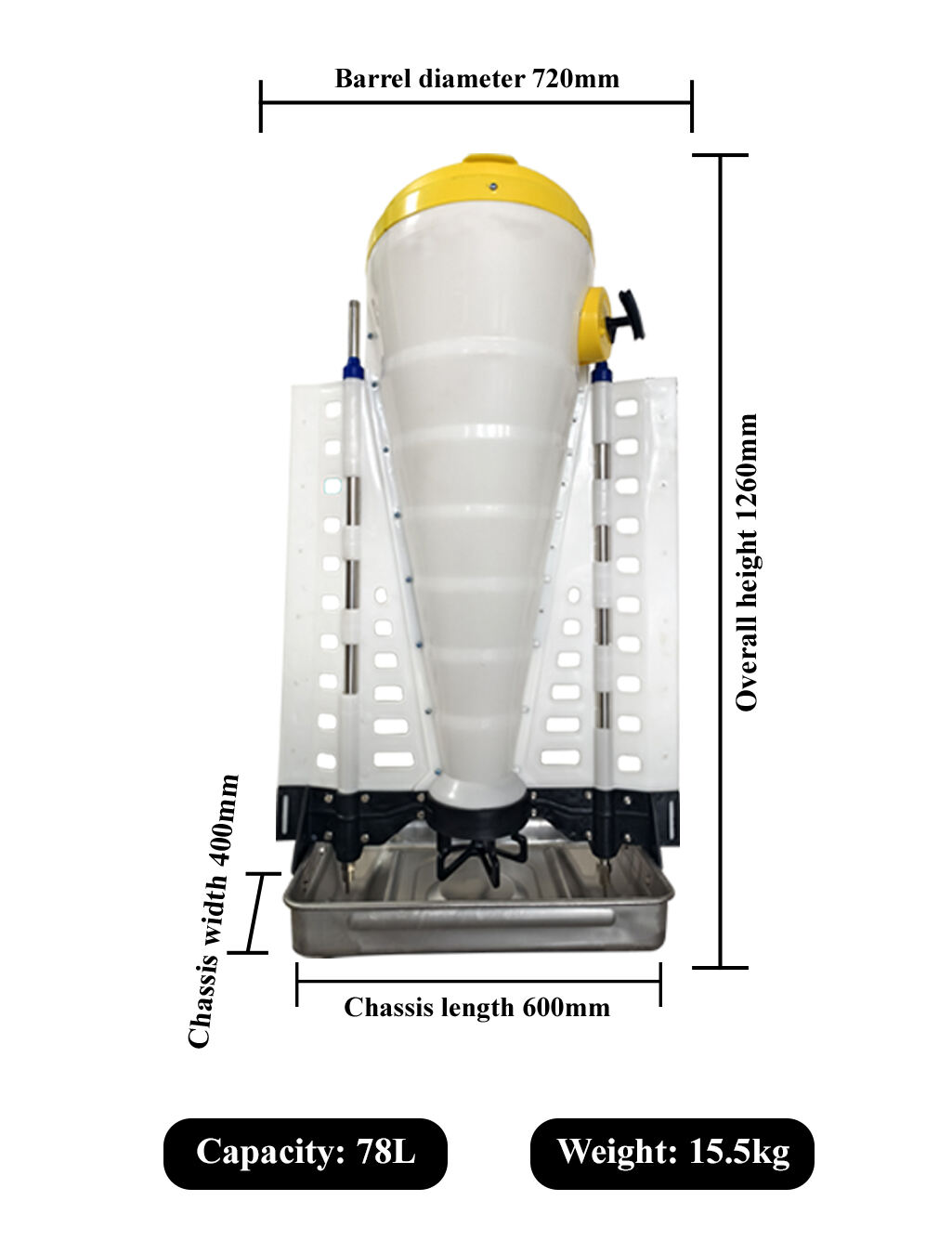

- Размер

- Детали

- Рекомендуемые товары

Описание

Этот сухой и влажный кормушка для свиней разработана для эффективного кормления отъемышей и откормочных свиней, обеспечивая оптимальный рост и снижение потерь корма. Она оснащена вместительным кормовым бункером объемом 60 л с интегрированным смесителем, предотвращающим образование мостиков в корме, что гарантирует бесперебойную подачу корма. Каждая кормушка рассчитана на 30–35 свиней, что делает ее идеальным решением для группового содержания в современных откормочных хозяйствах. Оптимизированная конструкция кормушки минимизирует потери корма, повышая экономическую эффективность и усвояемость корма. Для отъемышей (7–30 кг) кормушка оснащена одной поилкой, а для откормочных свиней (30–130 кг) — двумя поилками, что позволяет свиньям одновременно потреблять корм и воду, улучшая пищеварение и общую продуктивность. Дозирующий механизм над кормушкой обеспечивает точную подачу корма, а прочная конструкция гарантирует длительный срок службы. Эта кормушка обеспечивает гигиеничную, эффективную и трудосберегающую систему для фермерских хозяйств любого масштаба.

Сертификат

Детали

|

Идеально подходит для гранул и порошка В нижней части дозатора установлена пружина, которая поддерживает пространство между бункером для корма и дозирующей пластиной открытым, а не закрытым. Эти особенности позволяют дозатору для влажного и сухого корма свести к минимуму риск возникновения сводов при подаче корма. |

|

Предотвращает залипание корма надежное использование Имеется определённый угол наклона для обеспечения оптимальной подача корма: одновременно устанавливается пружинный рожок установлен для обеспечения того, чтобы отверстие между бункером и устройством дозированной подачи было чистым и не засорялось |

|

|

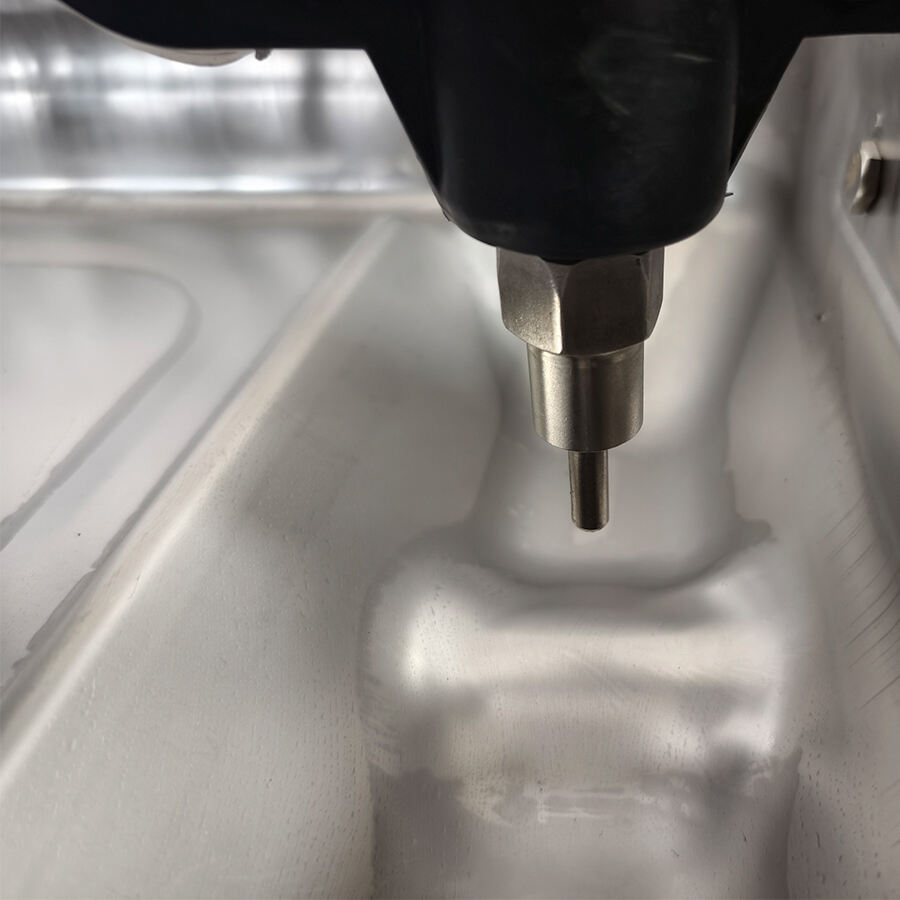

Регулировка и очистка Ручка регулировки разработана на основе эргономичного опыта и изготовлена из высококачественные материалы |

|

Концепция проектирования Дозатор спроектирован и изготовлен с учетом принципов легкой очистки, долговечности и высокой гигиены |

|