Компания Клапан контроля давления воды из материала АБС/ПП для системы поения свиней представляет собой сложное инженерное решение, специально разработанное для удовлетворения критически важных требований к управлению водными ресурсами в современных свиноводческих хозяйствах, и является незаменимым компонентом для поддержания оптимального уровня гидратации при одновременном обеспечении эффективного использования ресурсов на крупных сельскохозяйственных объектах. Этот передовой механизм регулирования давления включает в себя высококачественные материалы — акрилонитрилбутадиенстирол и полипропилен, создающие прочную основу, обеспечивающую исключительную устойчивость к химическому разрушению, перепадам температур и механическим нагрузкам, с которыми часто сталкиваются в сложных условиях животноводства. Стратегический выбор этих термопластичных соединений гарантирует превосходную стабильность размеров и долгосрочную надежность работы, что делает этот автоматический клапан регулирования водяного давления идеальным выбором для международных дистрибьюторов, ищущих надежные решения для своих портфелей сельскохозяйственного оборудования. Точная конструкция сборки клапана включает тщательно откалиброванные внутренние компоненты, которые автоматически регулируют параметры потока и давления воды, устраняя необходимость постоянного ручного контроля и обеспечивая постоянную доступность воды для животных при различных режимах эксплуатации. Эти сложные механизмы управления легко интегрируются в существующие системы поения свиней, обеспечивая беспроблемную совместимость как с традиционной системой водоснабжения, так и с современными автоматизированными системами кормления. Инновационная концепция дизайна клапана делает акцент на эффективности обслуживания, включая удобные точки регулировки и упрощённые протоколы очистки, которые сокращают простои в работе и увеличивают интервалы между техническим обслуживанием, тем самым повышая общую производительность системы и экономическую эффективность для конечных пользователей. Производственное совершенство остаётся главным приоритетом в процессе производства, где используются передовые технологии литья под давлением и прецизионная обработка, обеспечивающие постоянную точность размеров и высокое качество поверхности каждого изготовленного устройства. Тщательный отбор сырья проходит строгие протоколы оценки качества, гарантируя, что каждый компонент соответствует жёстким международным стандартам для сельскохозяйственного оборудования и сохраняет совместимость с различными условиями качества воды и системами химической обработки, применяемыми в современных свиноводческих комплексах. Процессы поверхностной обработки усиливают естественную устойчивость клапана к коррозии и росту бактерий, включая специализированные методы отделки, создающие гладкие, непроницаемые поверхности, идеально подходящие для поддержания гигиенических условий в системах водоснабжения животных. Эргономичный дизайн клапана обеспечивает простоту монтажа, позволяя использовать различные способы крепления и трубопроводные схемы, подходящие для разных планировок помещений и эксплуатационных требований. Возможности кастомизации выходят за рамки стандартных характеристик и позволяют адаптировать диапазоны давления, типы соединений и параметры регулирования потока для выполнения конкретных региональных требований или уникальных условий применения, запрашиваемых международными покупателями и производителями оригинального оборудования. Такие гибкие производственные подходы обеспечивают бесшовную интеграцию с существующей инфраструктурой и создают возможности для оптимизации систем с учётом местных условий давления воды, климатических факторов и специфических протоколов управления поголовьем. Философия стабильного качества лежит в основе всех этапов производственного процесса — от первоначального контроля материалов до окончательного тестирования продукции, обеспечивая, что каждый клапан соответствует одинаковым стандартам производительности независимо от партии или графика производства. Методология прочной конструкции клапана включает усиленные зоны напряжения и улучшенные уплотнительные механизмы, обеспечивающие надёжную работу в условиях постоянного цикла эксплуатации и сохраняющие точный контроль давления в течение длительного срока службы. Учет требований к экспорту влияет на конструкцию упаковки и защитные меры, обеспечивая целостность изделия при международных перевозках и хранении, а также способствуя эффективному управлению запасами в глобальных распределительных сетях. Компактная форма клапана оптимизирует эффективность доставки и снижает потребность в складских площадях, что делает его привлекательным вариантом для международных поставщиков, управляющих разнообразными ассортиментами продукции на нескольких рынках. Возможности сотрудничества с производителями оригинального оборудования и системными интеграторами открывают путь к разработке индивидуальных решений, направленных на удовлетворение конкретных региональных требований или уникальных задач, возникающих в международных свиноводческих операциях. Такие партнёрские подходы позволяют разрабатывать комплексные пакеты систем водоснабжения, в которых клапан выступает ключевым компонентом в рамках более крупных автоматизированных решений по управлению животноводством. Совместимость клапана с различными системами обработки воды и фильтрационным оборудованием обеспечивает его беспроблемную интеграцию с существующей инфраструктурой объекта, а его устойчивость к распространённым сельскохозяйственным химикатам и чистящим средствам сохраняет надёжность работы в течение регулярных циклов технического обслуживания. Ожидания долгосрочного сотрудничества с поставщиками подчёркивают постоянную доступность продукции, наличие технической поддержки и оперативных каналов связи, способствующих успешным деловым отношениям с международными дистрибьюторами и конечными клиентами. Проверенная надёжность конструкции и стабильность производства поддерживают уверенность в заключении долгосрочных соглашений о поставках и развитии присутствия на рынке в различных географических регионах. Передовые инженерные принципы, заложенные в конструкцию внутреннего механизма клапана, оптимизируют характеристики реакции на давление и точность регулирования потока, обеспечивая стабильную работу при изменяющихся условиях входного давления и колебаниях спроса на стороне потребителя, характерных для крупномасштабных систем поения свиней.

- Обзор

- Размер

- Детали

- Рекомендуемые продукты

Описание

Размер

Детали

|

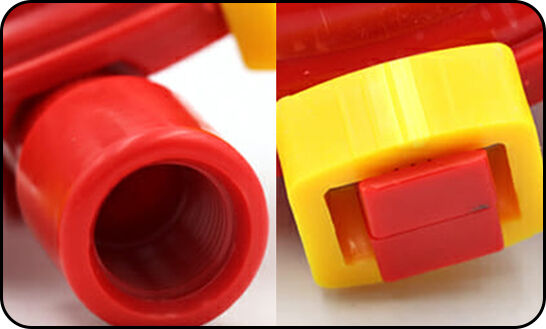

Конструкция ручки с шестью лапками, быстро и легко разбирается |

|

Кнопочный переключатель, удобный и быстрый доступ к воде |

|

|

Высококачественная силиконовая прокладка, надежное уплотнение, не подвержено протечкам |

|

Может обеспечивать водой весь свиной стан без потребления энергии |

|

|

Надежная и прочная винтовая фиксация, исключает утечку воды |

|

Сырье, гладкая и нежная поверхность, безопасная и нетоксичная |

|