O Anel Nasal para Gado de Plástico para Veterinária representa um avanço crítico nas práticas modernas de manejo pecuário, especificamente projetado para atender aos requisitos exigentes de veterinários profissionais, pecuaristas e operações agrícolas em todo o mundo. Este instrumento veterinário especializado atua como uma ferramenta essencial para o manejo de bovinos e modificação comportamental, desenvolvido com considerações anatômicas únicas das estruturas nasais bovinas. A construção em plástico oferece vantagens significativas em comparação com as alternativas tradicionais em metal, proporcionando maior segurança tanto para os animais quanto para os manipuladores, ao mesmo tempo que mantém a integridade estrutural necessária para um controle eficaz do gado. Veterinários profissionais reconhecem consistentemente a importância do uso de materiais adequados que minimizem a irritação nos tecidos e reduzam o risco de infecção, tornando os anéis nasais à base de plástico uma escolha cada vez mais preferida nos protocolos contemporâneos de manejo de bovinos. O processo de fabricação por trás desses instrumentos veterinários envolve técnicas sofisticadas de engenharia de polímeros que garantem flexibilidade ideal sem comprometer a durabilidade, criando produtos capazes de suportar as demandas físicas das operações diárias na fazenda, ao mesmo tempo que permanecem confortáveis para os animais. Equipes internacionais de sourcing e distribuidores especializados em suprimentos veterinários valorizam os padrões de qualidade consistentes mantidos ao longo do processo de produção, que inclui procedimentos rigorosos de testes para verificar a segurança dos materiais e a confiabilidade funcional em diversas condições ambientais.

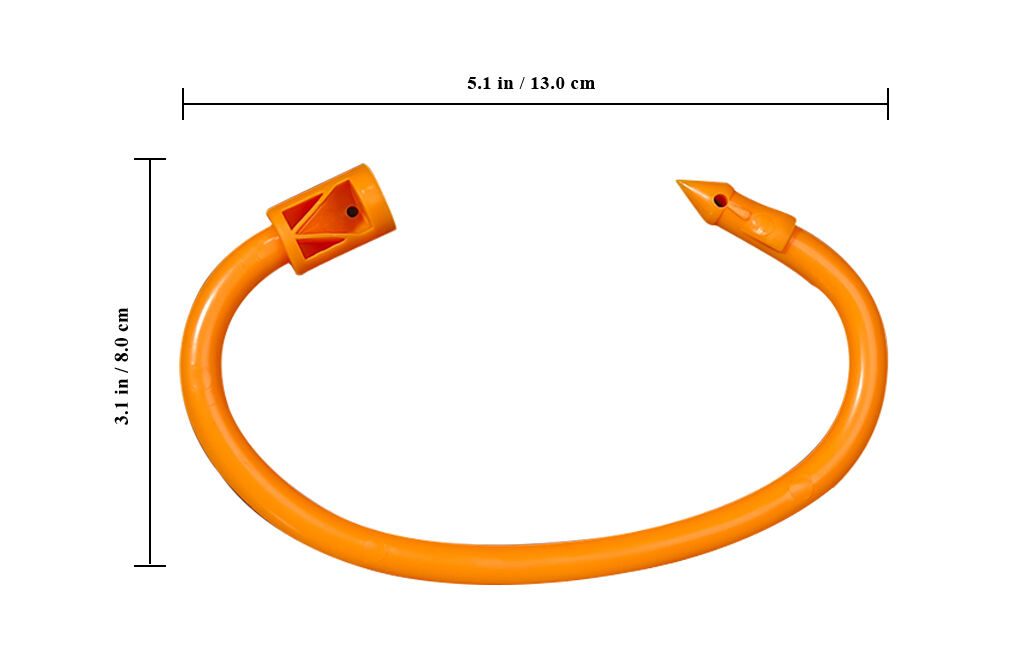

Do ponto de vista do design, o Anel Nasal para Gado de Plástico para Veterinária incorpora dimensões cuidadosamente calculadas que acomodam a variação natural da anatomia nasal bovina, garantindo um ajuste adequado em diferentes raças e grupos etários de gado. O tratamento superficial aplicado a esses instrumentos plásticos inclui frequentemente propriedades antimicrobianas que ajudam a manter os padrões de higiene em ambientes agrícolas, enquanto o acabamento liso evita abrasões nos tecidos que poderiam levar a complicações secundárias. Instalações fabris especializadas em equipamentos veterinários normalmente utilizam técnicas de moldagem por injeção que permitem um controle preciso sobre a espessura das paredes e a consistência estrutural, resultando em produtos com características de desempenho previsíveis, independentemente das variações entre lotes. O processo de seleção de materiais envolve uma avaliação extensiva de diferentes composições poliméricas para identificar formulações que ofereçam um equilíbrio ideal entre flexibilidade e resistência, assegurando que os anéis nasais possam ser instalados com segurança sem causar estresse excessivo aos animais. Os protocolos de controle de qualidade implementados durante a produção envolvem tipicamente múltiplas etapas de inspeção que verificam a precisão dimensional, a qualidade da superfície e a integridade do material, sustentando as expectativas de confiabilidade dos usuários profissionais em aplicações veterinárias e agrícolas. Fabricantes voltados à exportação costumam implementar medidas adicionais de garantia de qualidade que atendem aos requisitos regulamentares específicos de diferentes mercados internacionais, assegurando conformidade com os padrões de equipamentos veterinários em diversos países e regiões.

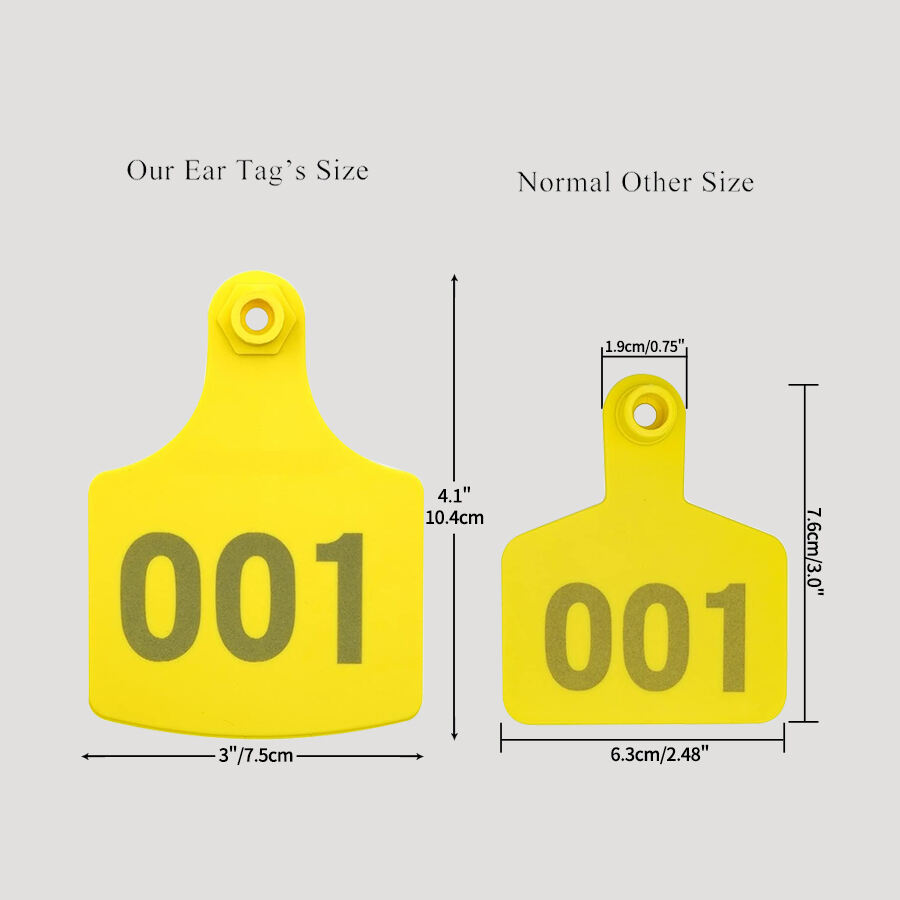

As possibilidades funcionais de personalização associadas a estas argolas plásticas vão além das opções básicas de tamanho, incluindo características especializadas, como cores de alta visibilidade para melhor identificação dos animais, superfícies texturizadas que facilitam a instalação segura e mecanismos de fechamento modificados que se adaptam a diferentes preferências de manuseio. Veterinários profissionais que trabalham com grandes operações pecuárias frequentemente exigem instrumentos que possam ser aplicados com eficiência em condições de campo, tornando os aspectos de design ergonômico particularmente importantes para o sucesso operacional. As características do material plástico proporcionam inerentemente maior estabilidade térmica em comparação com as alternativas metálicas, mantendo-se confortáveis para os animais ao longo das variações sazonais de temperatura, ao mesmo tempo em que preservam o desempenho estrutural. Os processos de fabricação podem ser adaptados para incorporar sistemas específicos de codificação por cores que apoiem os protocolos de gestão da fazenda, permitindo aos pecuaristas implementar esquemas de identificação visual que aumentem a eficiência geral do manejo do rebanho. O potencial de colaboração com parceiros OEM permite o desenvolvimento de soluções personalizadas que atendam a preferências regionais específicas ou requisitos operacionais únicos, apoiando as diversas necessidades dos mercados agrícolas internacionais. Fornecedores experientes neste setor normalmente mantêm capacidades de fabricação flexíveis, capazes de atender tanto às exigências de produtos padrão quanto a pedidos de personalização especializada, fomentando parcerias de longo prazo com distribuidores e usuários finais que valorizam um serviço ágil e capacidades de adaptação de produtos.

A adequação para diferentes ambientes agrícolas demonstra a versatilidade dos designs de argolas plásticas para o nariz, com desempenho comprovado em condições climáticas diversas, desde ambientes tropicais úmidos até regiões pastoris áridas. As propriedades de resistência química de formulações plásticas cuidadosamente selecionadas garantem compatibilidade com produtos químicos comuns e agentes de limpeza utilizados em procedimentos rotineiros de cuidados com o gado, mantendo a integridade do produto durante períodos prolongados de uso. Distribuidores profissionais de equipamentos agrícolas frequentemente enfatizam a importância da consistência do material ao compor estoques para mercados internacionais, tornando a confiabilidade do fornecedor um fator crucial nas decisões de seleção de produtos. A abordagem de fabricação normalmente incorpora sistemas automatizados de produção que asseguram tolerâncias dimensionais consistentes e qualidade superficial uniforme em grandes volumes de produção, atendendo às exigências de escala das principais operações agrícolas e cadeias de suprimento veterinário. A filosofia de consistência de qualidade integrada às operações de fabricação profissional atende à necessidade crítica de características de desempenho previsíveis das quais veterinários e pecuaristas dependem para obter bons resultados no manejo animal. Estruturas de cooperação internacional estabelecidas por fabricantes experientes frequentemente incluem serviços abrangentes de suporte técnico que auxiliam distribuidores e usuários finais na correta seleção de produtos e técnicas de aplicação, aumentando a satisfação geral do cliente e promovendo a implementação bem-sucedida de programas de manejo bovino. As considerações de compatibilidade com embalagem e logística incorporadas ao design do produto facilitam a distribuição eficiente por meio dos canais veterinários estabelecidos, assegurando que os produtos cheguem aos usuários finais em condição ideal, independentemente das distâncias de transporte ou requisitos de manuseio enfrentados nas cadeias de suprimento globais.