Les aiguilles de suture vétérinaires en acier inoxydable avec fil en acide polyglycolique ou en boyau chromé représentent un composant essentiel des interventions chirurgicales vétérinaires modernes, offrant aux distributeurs internationaux et aux professionnels des achats médicaux un accès à des instruments chirurgicaux de précision spécialement conçus pour les applications de santé animale. Ces aiguilles de suture spécialisées combinent les propriétés résistantes à la corrosion d’un acier inoxydable de haute qualité avec des matériaux de suture synthétiques et naturels avancés, créant ainsi une solution chirurgicale complète répondant aux besoins variés de fermeture des plaies rencontrés dans les pratiques vétérinaires du monde entier. L'intégration de matériaux synthétiques en acide polyglycolique et d'options traditionnelles en boyau chromé offre aux professionnels vétérinaires des choix polyvalents adaptés à différents types de tissus, durées de cicatrisation et procédures chirurgicales, allant des opérations de stérilisation courantes à des interventions orthopédiques complexes. La construction en aiguille d'acier inoxydable garantit des caractéristiques de pénétration constantes tout en maintenant l'intégrité structurelle lors des interventions chirurgicales exigeantes, particulièrement important dans les environnements vétérinaires où les variations de densité tissulaire et les différences anatomiques entre espèces exigent une performance fiable des instruments. Les procédés de fabrication de ces aiguilles de suture vétérinaires impliquent généralement des techniques d'usinage de précision permettant de créer des pointes d'aiguille tranchantes et uniformes, capables de minimiser les traumatismes tissulaires lors de l'insertion tout en assurant des points d'attache solides pour les matériaux de suture intégrés. Le composant en acide polyglycolique offre des taux d'absorption prévisibles dans les milieux tissulaires, ce qui le rend particulièrement adapté aux applications de suture interne où les procédures de retrait entraîneraient un stress supplémentaire pour les patients animaux. En revanche, l'option en boyau chromé assure une compatibilité naturelle avec les systèmes biologiques tout en présentant des caractéristiques d'absorption différentes, que les chirurgiens vétérinaires peuvent choisir selon les exigences spécifiques de la procédure et les attentes de cicatrisation. Les traitements de surface appliqués aux composants en acier inoxydable incluent souvent des opérations de polissage et de passivation améliorant la biocompatibilité, tout en réduisant les irrégularités de surface pouvant potentiellement retenir des contaminants ou provoquer des irritations tissulaires pendant les interventions chirurgicales. La constance de qualité constitue une exigence fondamentale pour les fournisseurs internationaux desservant les marchés vétérinaires, où la fiabilité des instruments influence directement les résultats chirurgicaux et les normes de bien-être animal à travers différentes régions géographiques et cadres réglementaires. Les approches de fabrication orientées vers l'exportation mettent généralement l'accent sur des protocoles de production standardisés garantissant une cohérence d'un lot à l'autre, quel que soit le marché destinataire, soutenant ainsi les distributeurs qui desservent plusieurs pays ayant des normes de pratique vétérinaire et des exigences réglementaires variées. Les possibilités de personnalisation dans cette catégorie de produits vont au-delà des spécifications de base concernant le calibre et la longueur des aiguilles, incluant des géométries de pointe spécialisées optimisées pour des applications vétérinaires spécifiques, telles que des aiguilles courbées pour les interventions dans les cavités internes ou des configurations droites pour la fermeture de plaies externes. L'offre double en matériaux de suture tient compte des préférences vétérinaires variées et des protocoles opératoires, permettant aux distributeurs de servir des clientèles diversifiées sans devoir gérer des stocks distincts pour les matériaux de suture synthétiques et naturels. Les considérations liées à l'emballage de ces instruments chirurgicaux vétérinaires mettent généralement l'accent sur des méthodes de présentation stérile préservant l'intégrité du produit tout au long des processus d'expédition internationale, tout en facilitant la gestion efficace des stocks pour les fournisseurs vétérinaires et les services d'achat hospitaliers. Les relations collaboratives avec les fabricants d'équipements d'origine (OEM) visent souvent à développer des variantes spécifiques à chaque application, répondant à des exigences particulières dans les sous-spécialités vétérinaires, comme la médecine des animaux exotiques, la chirurgie des grands animaux ou des procédures spécialisées nécessitant des caractéristiques modifiées d’aiguilles ou des combinaisons alternatives de matériaux de suture. Le marché vétérinaire international exige une fiabilité constante de la chaîne d'approvisionnement, notamment pour les consommables chirurgicaux essentiels dont les ruptures de stock peuvent directement affecter les capacités de soins aux animaux et les interventions chirurgicales d'urgence. Les partenariats à long terme dans ce secteur mettent généralement l'accent sur les capacités d'assistance technique en complément de la livraison des produits, reconnaissant que les distributeurs vétérinaires ont souvent besoin de ressources éducatives et de conseils d'application pour servir efficacement leur clientèle finale. L'expérience en fabrication d'instruments médicaux de précision se traduit directement par une compréhension des tolérances critiques et des normes de qualité nécessaires aux applications chirurgicales vétérinaires, où une défaillance instrumentale ou une performance incohérente peut avoir de graves conséquences tant pour les patients animaux que pour les professionnels vétérinaires. La construction en acier inoxydable assure une excellente compatibilité avec les protocoles d'autoclavage couramment utilisés dans les établissements vétérinaires, tandis que les matériaux de suture intégrés conservent leurs caractéristiques de manipulation et leurs propriétés de résistance à la traction tout au long des procédures standard de stérilisation. Le positionnement sur le marché de ces instruments vétérinaires spécialisés reflète la sophistication croissante des services de santé animale dans le monde entier, où des techniques chirurgicales avancées auparavant réservées à la médecine humaine sont de plus en plus adoptées pour les animaux de compagnie et les animaux d'élevage. Les opportunités de coopération OEM impliquent fréquemment le développement de configurations d'emballage ou de documentation spécifiques à chaque région, facilitant la conformité réglementaire sur différents marchés internationaux tout en préservant les spécifications fondamentales du produit et ses caractéristiques de performance. Les considérations liées à la logistique incluent la stabilité thermique pendant le transport, des conceptions d'emballage compactes optimisant l'efficacité du transport, ainsi que des systèmes d'emballage protecteurs empêchant les dommages aux pointes d'aiguilles et à l'intégrité des matériaux de suture durant les manipulations et les phases de stockage.

Aiguilles de suture vétérinaires en acier inoxydable avec fil en polyglycolide ou catgut chromique

-

Aiguille tranchante et durable – Fabriquée en acier inoxydable de haute qualité pour des sutures précises, solides et fiables lors des interventions vétérinaires.

-

Options de suture résorbable – Comprend du polyglycolide ou du catgut chromé pour une résorption adaptée et une réaction tissulaire minimale.

-

Prêt à l'emploi et stérile – Suture préalablement fixée et emballage stérile garantissant commodité, sécurité et gain de temps pendant les opérations.

-

Application chirurgicale versatile – Adaptée pour les sutures internes, externes et des tissus mous chez les animaux de rente et les petits animaux.

-

Contrôle et solidité améliorés – Design courbe et grande résistance à la traction assurant un positionnement précis et une résistance optimale à la rupture.

- Vue d'ensemble

- Détails

- Produits recommandés

Informations sur les paramètres du produit

| Nom | Aiguille de suture vétérinaire |

| Modèle | 10 bâtons/tube |

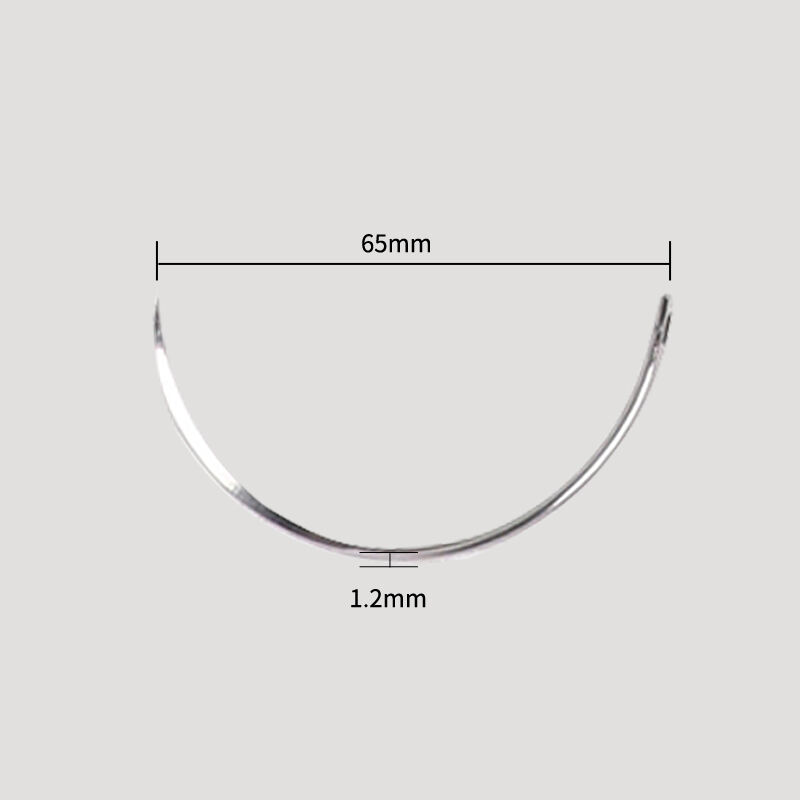

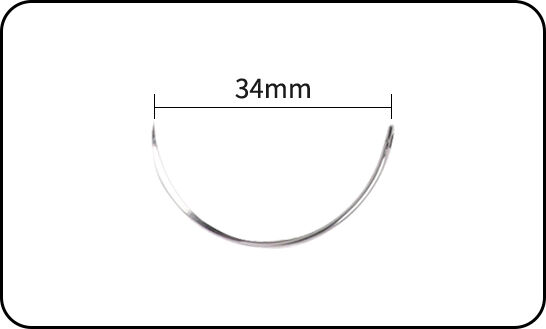

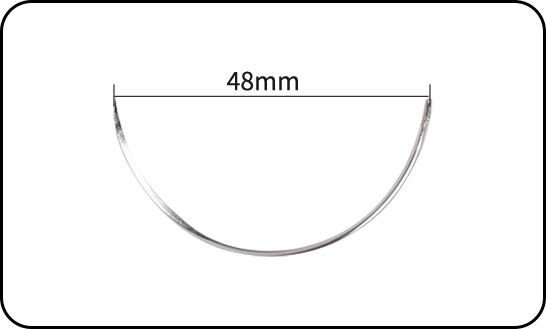

| Spécification | 11*34mm 12*40mm 12*48mm 12*65mm |

| Application | Utilisé pour les sutures et ligatures en chirurgie vétérinaire |

| Caractéristiques | La lame est tranchante, durable et fabriquée avec un bon matériau |

Description

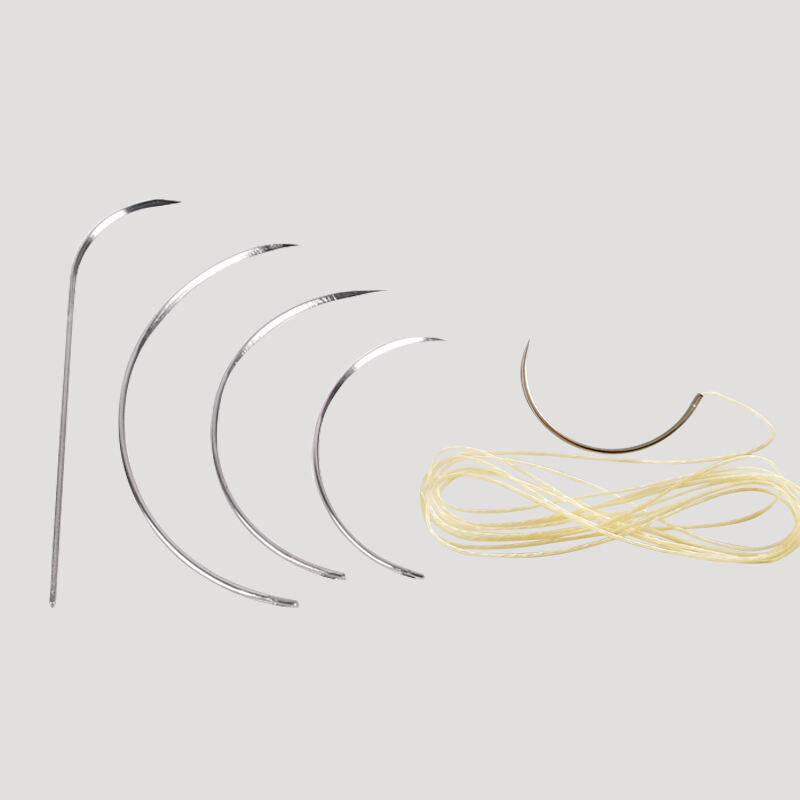

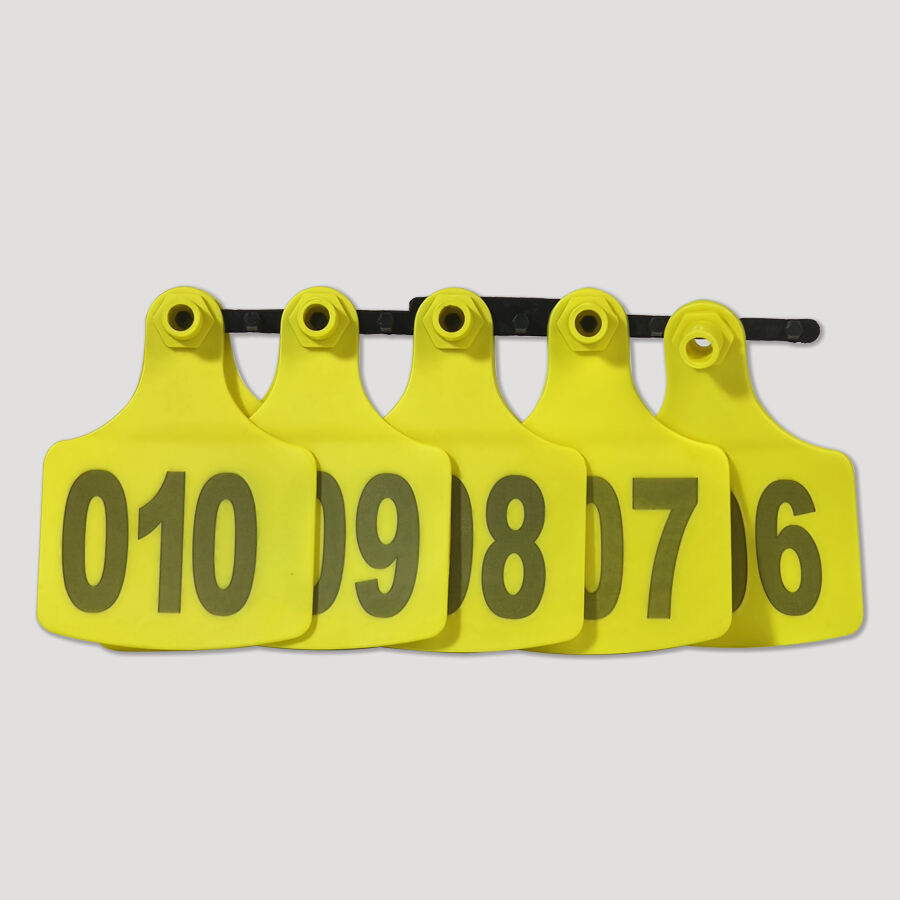

Cet ensemble d'aiguilles à suture vétérinaire est conçu pour une utilisation professionnelle lors de procédures chirurgicales animales et pour des applications exigeantes de couture de fourrure. L'ensemble comprend 10 aiguilles à suture en argent de haute qualité, fabriquées en acier inoxydable durable et dotées d'un fini poli pour assurer une pénétration douce et une longue durée de vie. Chaque aiguille possède une pointe courbée et tranchante permettant un pointage précis, réduisant les traumatismes tissulaires et favorisant une cicatrisation efficace lors des interventions vétérinaires. Ces aiguilles sont polyvalentes, ce qui les rend adaptées non seulement à la suture vétérinaire, mais aussi à des projets exigeants de couture de fourrure. Pour plus de commodité et de sécurité, l'ensemble est fourni avec un étui de protection permettant de garder les aiguilles organisées et sécurisées entre chaque utilisation. Que ce soit dans des cliniques vétérinaires, des fermes ou des ateliers, cet ensemble d'aiguilles à suture offre la fiabilité et les performances nécessaires pour des applications professionnelles, alliant solidité, précision et facilité d'utilisation dans un design pratique et robuste.

Détails

|

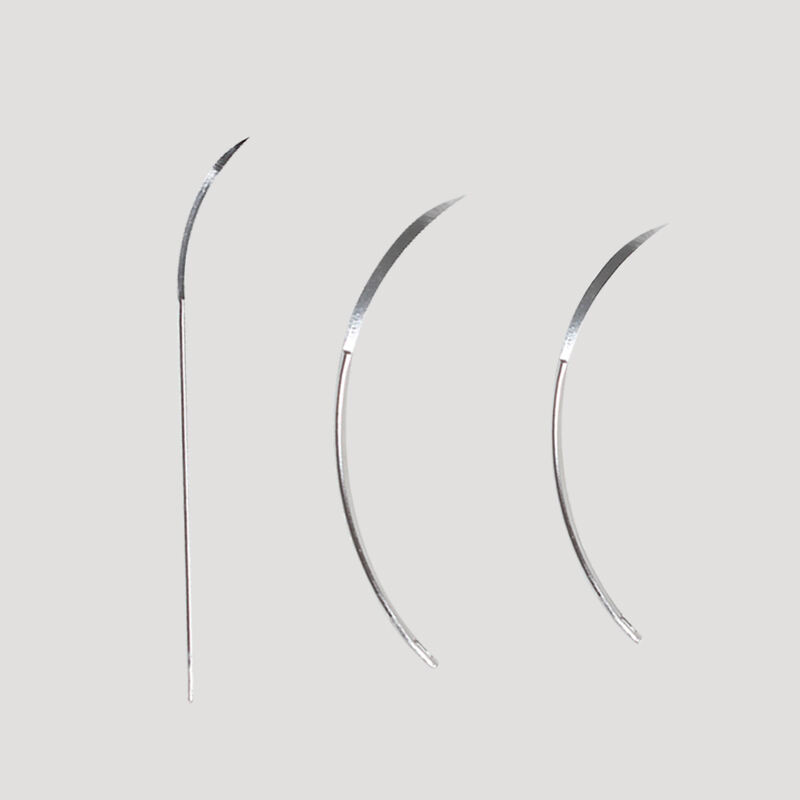

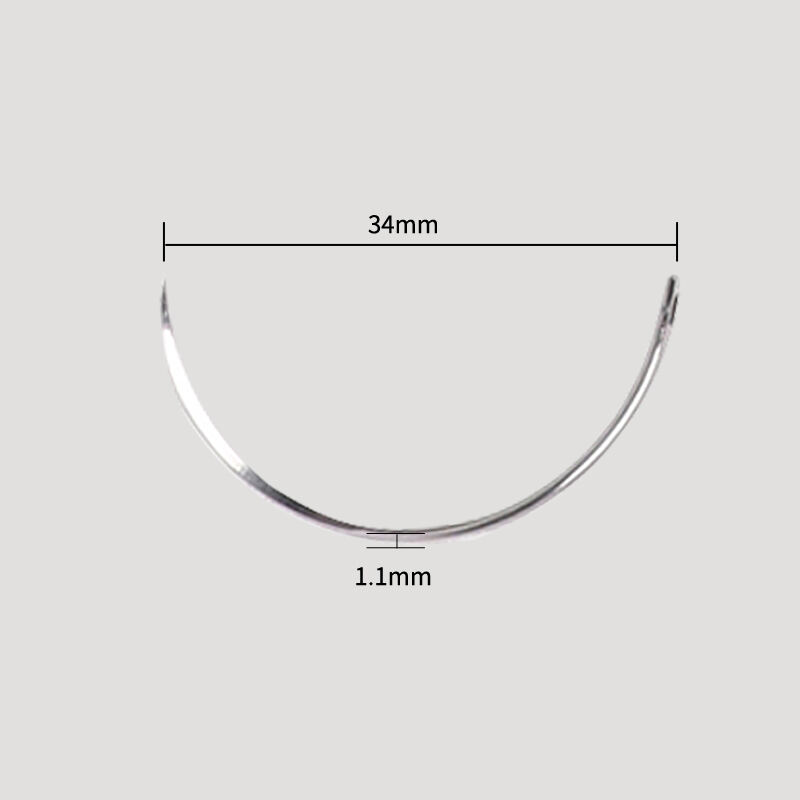

La pointe de l'aiguille à suture est triangulaire et l'arc est semi-circulaire. Le diamètre extérieur est de 1,1 mm, et la distance en ligne droite est de 34 mm, ce qui est généralement utilisé pour les porcelets. |

|

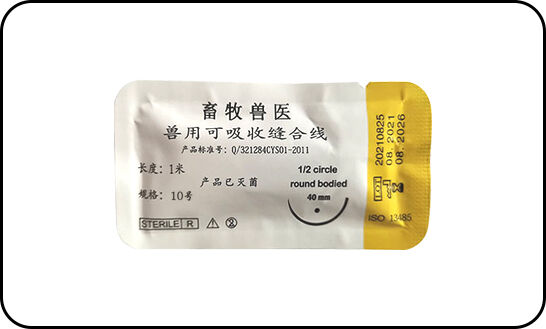

La pointe de l'aiguille à suture est triangulaire et l'arc est semi-circulaire. Le diamètre extérieur est de 1,2 mm, et la distance en ligne droite est de 40 mm. Elle est généralement utilisée pour les porcs de petite et moyenne taille. |

|

|

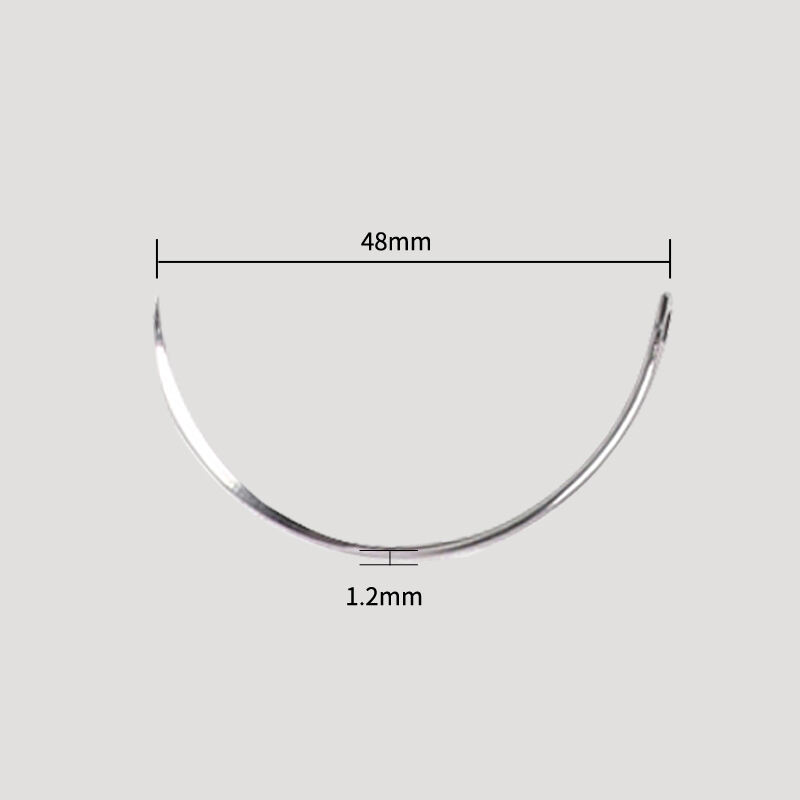

La pointe de l'aiguille à suture est triangulaire et l'arc est semi-circulaire. Le diamètre extérieur est de 1,2 mm, et la distance en ligne droite est de 48 mm, ce qui est généralement utilisé par les porcs moyens et grands porcs. |

|

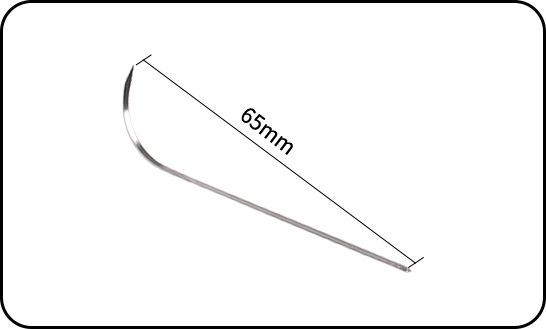

La pointe de l'aiguille à suture est triangulaire et l'arc est semi-courbé. Le diamètre extérieur est de 1,2 mm, et la distance en ligne droite est de 65 mm, ce qui est géné- ralement utilisé par les grands porcs et d'autres animaux de grande taille. |

|

|

Il convient pour la chirurgie intestinale des bovins, ainsi que la chirurgie de l'hernie ombilicale des porcs et moutons de moins de 30 kg, chirurgie de castration, etc. |

|

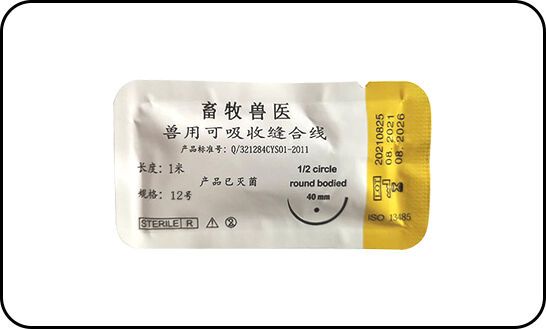

Il convient pour la suture du porc et utérus de mouton, ombilic chirurgie de hernie du porc et moutons de moins de 80 kg, castration chirurgie, etc. |

|

|

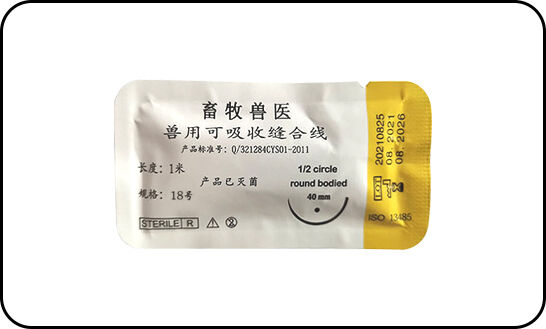

Adapté pour la suture utérine des vaches et des porcs et chirurgie de hernie ombilicale du porc et du mouton intervention sur plus de 80 kg, bélier ligature et castration, etc. |

|

Adapté pour césarienne chez les bovins suture utérine sectionnée, gastrectomie chez les bovins, suturer la péritoine et d'autres muscles couches, suture de l'épiderme, Vasectomie chez les chevaux |

|