Le Aromatisateur continu avec fonction pulvérisation 30 ml représente une approche sophistiquée des solutions de distribution précise de liquides, conçue spécifiquement pour répondre aux exigences rigoureuses d'applications professionnelles dans divers secteurs industriels où une délivrance de fluide contrôlée, constante et fiable est primordiale. Ce système de distribution innovant combine les fonctionnalités d'un arrosage continu avec des options de pulvérisation polyvalentes, le tout contenu dans une capacité compacte de trente millilitres qui optimise la portabilité tout en maintenant des normes de performance professionnelles. La conception à double fonction répond à la demande croissante du marché pour des équipements capables de passer sans heurt entre différentes méthodes d'application, éliminant ainsi le besoin de plusieurs outils et rationalisant l'efficacité opérationnelle dans les environnements de laboratoire, industriels, agricoles et commerciaux spécialisés. La philosophie d'ingénierie derrière ce dispositif d'arrosage continu met l'accent sur des mécanismes de contrôle de précision garantissant des motifs de distribution uniformes, qu'il fonctionne en mode écoulement continu ou utilise la fonction de pulvérisation intégrée, ce qui en fait un outil indispensable pour les professionnels exigeant des résultats constants dans divers scénarios d'application. Le facteur de forme compact de la capacité de trente millilitres établit un équilibre optimal entre fonctionnalité et maniabilité, offrant un volume suffisant pour des sessions d'utilisation prolongées tout en conservant les avantages ergonomiques facilitant une manipulation précise lors d'opérations délicates. Les méthodes de fabrication de ce type d'équipement de distribution spécialisé impliquent généralement des techniques de moulage de précision et une attention particulière à l'alignement des composants internes afin d'assurer un fonctionnement fluide tant du mécanisme d'arrosage continu que de la fonction de pulvérisation, avec un accent particulier mis sur la création de joints étanches et le maintien d'une répartition uniforme de la pression dans tout le système. Les traitements de surface et les procédés de finition utilisés en production visent à créer des surfaces extérieures lisses, faciles à nettoyer, résistantes aux interactions chimiques tout en offrant une adhérence sécurisée essentielle pour une utilisation professionnelle dans diverses conditions environnementales. Les considérations de conception vont au-delà de la fonctionnalité de base pour inclure des éléments liés à l'expérience utilisateur tels que la réactivité de la gâchette, la constance du débit et la transition fluide entre les modes de fonctionnement, garantissant ainsi que les opérateurs puissent rester concentrés sur leurs tâches principales sans être distraits par des limitations matérielles ou des complexités opérationnelles. Les possibilités de personnalisation pour ce type d'équipement de distribution incluent souvent des modifications des configurations d'embouts, des mécanismes de réglage du débit, des matériaux spécialisés assurant la compatibilité chimique, ainsi que des améliorations ergonomiques adaptées aux exigences spécifiques d'un secteur ou aux préférences des utilisateurs. La polyvalence du dispositif d'arrosage continu avec fonction de pulvérisation le rend particulièrement adapté aux applications dans les laboratoires de recherche où la distribution précise de réactifs est critique, aux environnements agricoles nécessitant l'application contrôlée de traitements ou de nutriments, aux processus industriels de contrôle qualité exigeant une préparation d'échantillons constante, et aux opérations de fabrication spécialisées où l'application uniforme d'un revêtement ou d'un traitement influence directement la qualité du produit. La philosophie de cohérence de qualité dans la production de tels instruments de précision met l'accent sur des protocoles de tests rigoureux tout au long du processus de fabrication, en accordant une attention particulière à l'assurance que les fonctions continues et de pulvérisation conservent leurs caractéristiques de performance spécifiées au fil des cycles d'utilisation prolongés et dans des conditions environnementales variables. Les considérations logistiques orientées vers l'exportation incluent des conceptions d'emballage robustes protégeant les mécanismes internes délicats pendant le transport international, une documentation complète facilitant le traitement douanier et la configuration par l'utilisateur final, ainsi que des choix de matériaux conformes aux réglementations internationales de sécurité et environnementales dans les divers marchés mondiaux. L'approche collaborative pour les partenariats OEM et ODM implique généralement des consultations approfondies afin de comprendre les besoins spécifiques des clients, suivies d'un développement itératif de la conception qui équilibre faisabilité technique et objectifs de positionnement sur le marché, garantissant ainsi que les versions personnalisées conservent les caractéristiques fondamentales de performance tout en intégrant des améliorations ou éléments de marque spécifiques au client. Les facteurs de compatibilité d'emballage et de logistique prennent en compte les conditions de stockage préservant l'intégrité du produit pendant de longues périodes en entrepôt, les configurations d'expédition minimisant les risques de dommages en transit, et les documents accompagnants facilitant une distribution efficace à travers divers canaux, notamment les ventes directes, les réseaux de distributeurs et les plateformes de commerce électronique. Les attentes de coopération à long terme avec les fournisseurs englobent généralement un support technique continu pour l'optimisation du produit, une communication réactive concernant d'éventuelles améliorations ou modifications, un planning de production flexible permettant de s'adapter à des schémas de demande variables, ainsi qu'un développement collaboratif de fonctionnalités de nouvelle génération répondant aux exigences évolutives du marché tout en maintenant la compatibilité ascendante avec les systèmes et accessoires existants. La construction de qualité professionnelle assure un fonctionnement fiable dans diverses conditions environnementales, tandis que la conception intuitive facilite une formation rapide et une adoption aisée par le personnel possédant différents niveaux d'expérience technique, ce qui en fait un choix attrayant pour les organisations souhaitant standardiser leur équipement de distribution sur plusieurs sites ou départements. Dans les scénarios d'approvisionnement B2B internationaux, on privilégie souvent les équipements démontrant des caractéristiques de performance constantes, une disponibilité fiable de la chaîne d'approvisionnement et un support technique complet, éléments fondamentaux pris en compte lors du développement et de la production de solutions de distribution de précision telles que ce dispositif d'arrosage continu avec fonction de pulvérisation, garantissant ainsi que les décisions d'achat soutiennent les objectifs opérationnels à long terme tout en offrant des avantages tactiques immédiats dans les applications quotidiennes.

Aromatisateur continu avec fonction pulvérisation 30 ml

-

Dosage précis et efficace – Capacité de 30 ml avec des graduations claires pour une administration continue et précise des médicaments.

-

Double fonctionnalité – Combine trempage et pulvérisation en un seul outil, augmentant ainsi la polyvalence pour divers traitements.

-

Construction robuste et adaptée à l'environnement agricole – Fabriqué en matériaux résistants à la corrosion pour une utilisation durable dans les environnements difficiles.

-

Ergonomique et facile d'utilisation – Poignée confortable et conception à remplissage rapide réduisant la fatigue et améliorant l'efficacité du travail.

-

Utilisation polyvalente pour le bétail – Idéal pour traiter les moutons, les chèvres, les porcs et autres animaux avec un minimum de stress et sans déversement.

- Vue d'ensemble

- Détails

- Points de vente clés

- Produits recommandés

Informations sur les paramètres du produit

| Nom | Dispenseur de médicaments pour usage vétérinaire |

| Matériau | Matériaux polymères bruts |

| Spécification | 3ml-30ml (augmentation de 1ml par tour) |

| Application | Administrez divers médicaments pour animaux |

| Caractéristiques | Dose ajustable, graduations claires, embout en métal résistant aux morsures |

Description

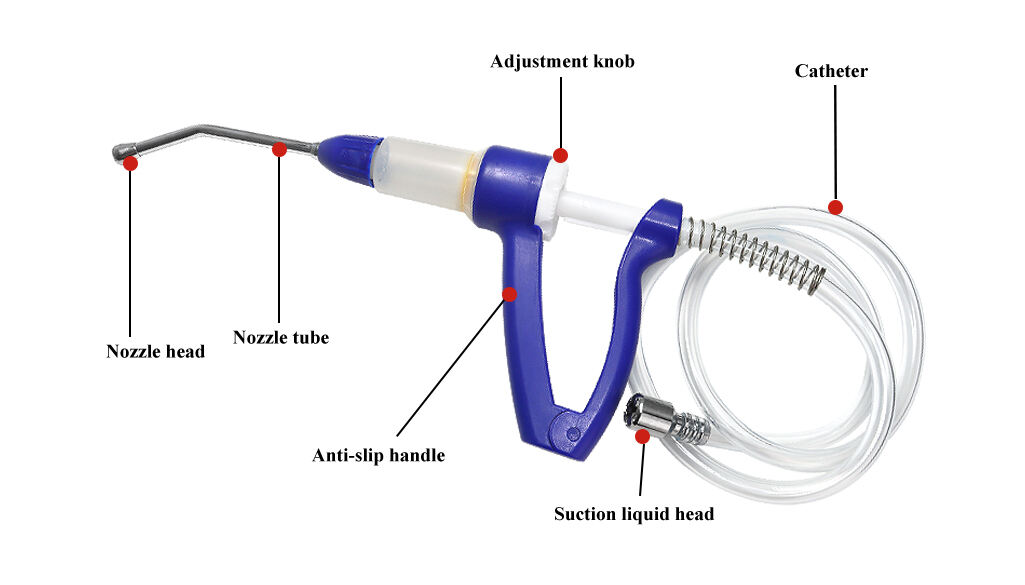

Le pistolet doseur en plastique WQ 30 ml est un outil fiable conçu pour une utilisation vétérinaire efficace, alliant durabilité, précision et facilité d'utilisation. Avec une plage d'ajustement de dose de 3 à 30 ml, cette seringue automatique à dose élevée et continue permet une administration précise et régulière pour le bétail. Légère mais robuste, elle est fabriquée en plastique de haute qualité et comporte des composants métalliques de première classe assurant une longue durée de vie. Le pistolet doseur peut être connecté à un réservoir à médicament de 2,5 L porté dans le dos, ce qui le rend très pratique pour les grandes exploitations.

Chaque unité est pré-testée à 100 %, les inspections effectuées par des tiers étant acceptées pour garantir la qualité. La production est supervisée par un service de contrôle rigoureux, assurant ainsi la conformité aux normes élevées de fabrication. En tant que produit breveté issu directement de l'usine, il propose des prix compétitifs et une livraison fiable. Des ouvriers qualifiés fabriquent chaque seringue avec soin, et la production sur mesure est possible afin de satisfaire des exigences spécifiques. Ce pistolet doseur constitue une solution idéale pour un dosage animalier précis, sûr et efficace.

Certificat

Détails

Points de vente clés

|

Cathéter souple et durable Matières premières de haute qualité, non toxiques et inodores, forte résistance au vieillissement |

|

Tête de buse en métal Matériau métallique, anti-morsure et durable, ne blesse pas la bouche de l'animal |

|

|

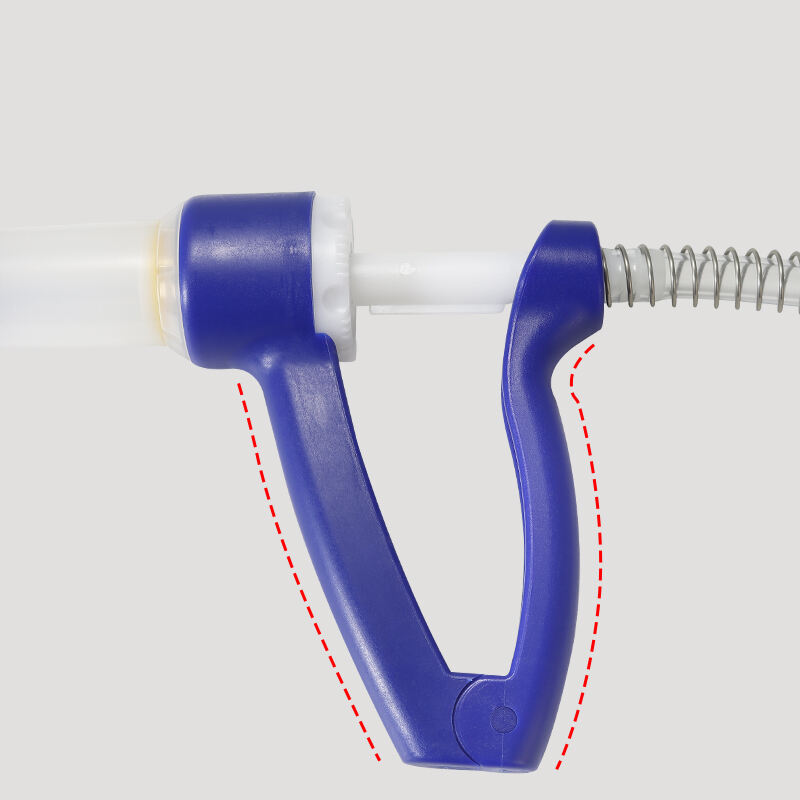

Poignée confortable Conception de la poignée avec rainure, poignée ergonomique, confortable et ne fatigue pas les mains |

|

Écrou réglable Bouton de réglage doseur, régalable, petite erreur, conservation du médicament liquide |

|

|

Type spray, embout d'alimentation Pulvérisation de médicament liquide, faible impact, répartition uniforme du médicament liquide, pratique pour l'alimentation des animaux |