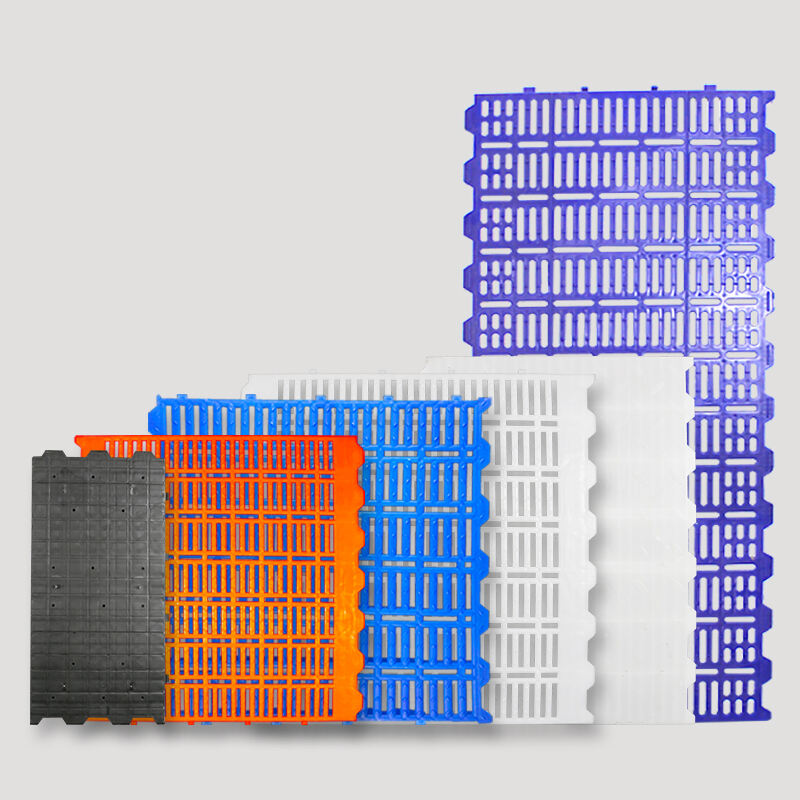

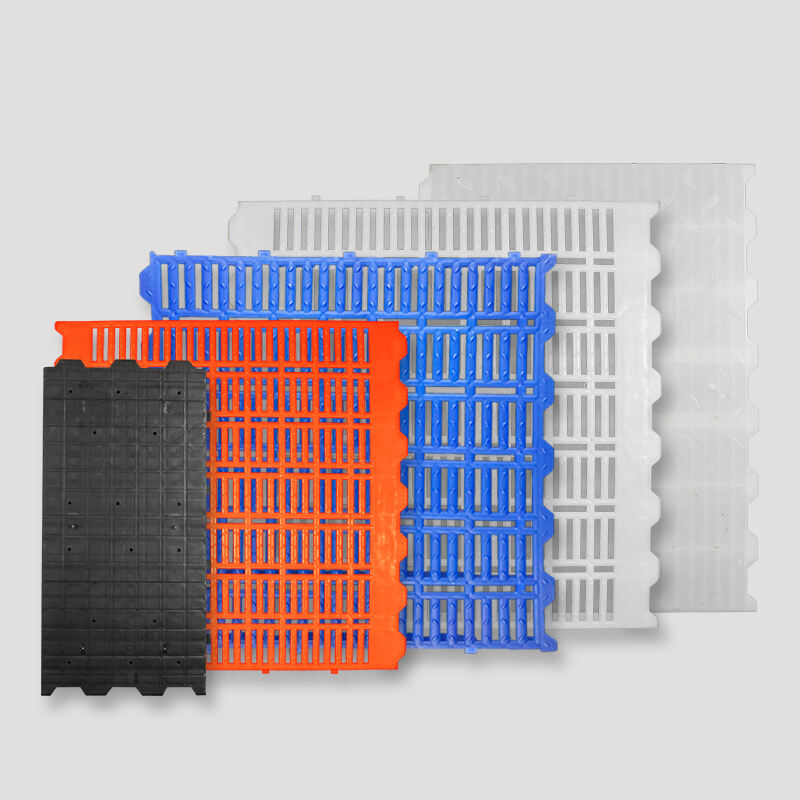

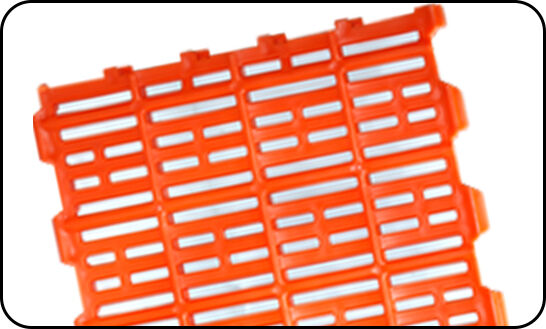

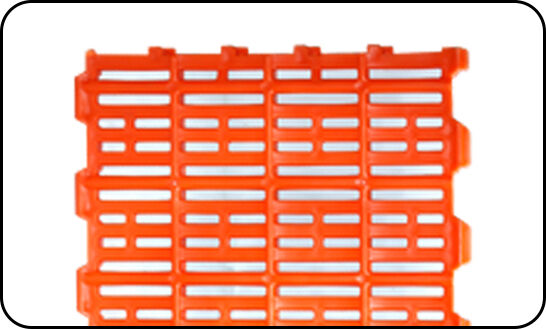

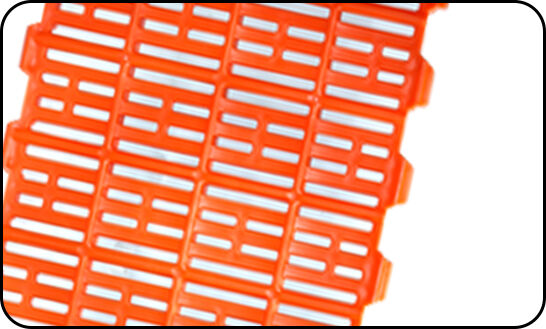

La Polipropileno PP Piso de lamas Para Casa de Cerdos Tamaño Personalizado representa una solución sofisticada de pavimento diseñada específicamente para instalaciones modernas de cría de porcinos, ofreciendo a los productores ganaderos y desarrolladores de infraestructuras agrícolas una alternativa avanzada frente a los sistemas tradicionales de losas de hormigón y metal. Este sistema especializado de pavimento agrícola aprovecha las propiedades inherentes del material polipropileno para ofrecer características de rendimiento excepcionales que abordan los desafíos únicos encontrados en entornos de granjas porcinas, donde deben equilibrarse cuidadosamente la durabilidad, el mantenimiento de la higiene y las consideraciones de bienestar animal. La capacidad de personalización en el tamaño de esta solución de pavimento permite una adaptación precisa a diversas distribuciones de instalaciones, desde operaciones agrícolas a pequeña escala hasta complejos comerciales grandes de producción porcina, asegurando una utilización óptima del espacio y eficiencia operativa en distintas configuraciones arquitectónicas. La selección del polipropileno como material para aplicaciones de pavimento ganadero se debe a su notable resistencia a la humedad, agentes químicos de limpieza y a los efectos corrosivos de los desechos animales, lo que lo hace especialmente adecuado para entornos en los que los materiales convencionales pueden deteriorarse rápidamente bajo exposición constante a compuestos de amoníaco y ácidos orgánicos. La estructura molecular del polipropileno proporciona una estabilidad dimensional excepcional ante las fluctuaciones de temperatura comúnmente presentes en edificios agrícolas, manteniendo al mismo tiempo suficiente flexibilidad para soportar las condiciones dinámicas de carga generadas por el movimiento del ganado y las actividades de mantenimiento de la instalación. Los procesos de fabricación empleados en la producción de estos sistemas de losas suelen implicar técnicas de moldeo de precisión que garantizan una exactitud dimensional consistente y características de textura superficial, permitiendo un acoplamiento fiable entre paneles adyacentes mientras se mantienen capacidades de drenaje adecuadas, esenciales para una gestión eficaz de residuos. El aspecto de personalización de esta solución de pavimento va más allá de simples modificaciones dimensionales e incluye diversas opciones de texturizado superficial, configuraciones de separación entre listones y patrones de refuerzo estructural que pueden adaptarse a prácticas específicas de manejo ganadero y requisitos operativos de la instalación. Las consideraciones sobre el tratamiento superficial del pavimento de listones de polipropileno suelen incorporar texturas antideslizantes que proporcionan tracción adecuada para el movimiento de los animales, facilitando al mismo tiempo procedimientos de limpieza exhaustivos, logrando un equilibrio crítico entre la seguridad animal y la eficiencia de mantenimiento, lo cual impacta directamente en la productividad general de la instalación. La flexibilidad de diseño inherente al procesamiento del polipropileno permite incorporar canales de drenaje especializados, características de recolección de residuos y elementos que mejoran la ventilación, contribuyendo así a una gestión mejorada de la calidad del aire dentro de las estructuras de alojamiento porcino. La naturaleza no porosa de las superficies de polipropileno correctamente fabricadas reduce significativamente el potencial de colonización bacteriana en comparación con los pisos tradicionales de hormigón, apoyando protocolos de bioseguridad mejorados que son cada vez más importantes en los entornos modernos de producción ganadera. Las consideraciones de instalación para losas de polipropileno personalizadas suelen implicar enfoques modulares que se adaptan a la infraestructura existente del edificio, a la vez que brindan flexibilidad para futuras modificaciones o ampliaciones de la instalación, lo que convierte a esta solución de pavimento en una opción particularmente atractiva para operaciones agrícolas que planean estrategias de crecimiento a largo plazo. Las propiedades de resistencia química del polipropileno hacen que estos sistemas de pavimento sean compatibles con una amplia gama de protocolos de desinfección y agentes limpiadores comúnmente utilizados en instalaciones ganaderas, asegurando que se puedan mantener rigurosos estándares de saneamiento sin comprometer la integridad del material durante períodos prolongados de servicio. La adquisición internacional de sistemas de losas de polipropileno requiere una atención cuidadosa a las normas de calidad de fabricación, especificaciones de materiales y tolerancias dimensionales que deben cumplir con los códigos locales de construcción y regulaciones de manejo ganadero en los mercados de destino. Los proveedores orientados a la exportación de estas soluciones de pavimento suelen mantener programas completos de garantía de calidad que aseguran un rendimiento consistente del producto en diferentes lotes de producción, respaldando los requisitos de fiabilidad de distribuidores internacionales y usuarios finales que dependen de características predecibles del material para sus decisiones de planificación de instalaciones. El proceso de colaboración entre compradores extranjeros y fabricantes de pavimentos de polipropileno suele incluir consultas técnicas detalladas para establecer dimensiones óptimas de los listones, requisitos de carga y características superficiales que se alineen con prácticas específicas de manejo ganadero y parámetros de diseño de instalaciones. Las oportunidades de cooperación OEM y ODM en esta categoría de productos frecuentemente incluyen opciones de color personalizadas, tratamientos superficiales especializados y características integradas de accesorios que mejoran la funcionalidad del sistema base de pavimento, manteniendo al mismo tiempo la compatibilidad con la infraestructura existente de la instalación. Las consideraciones de embalaje y logística para el envío internacional de losas de polipropileno personalizadas requieren una atención cuidadosa a la protección del producto, la eficiencia dimensional y los requisitos de manipulación, minimizando así los costos de transporte y asegurando la integridad del producto a lo largo de toda la cadena de distribución. Las relaciones a largo plazo con proveedores en el sector de pavimentos agrícolas suelen enfatizar la entrega consistente de calidad, soporte técnico ágil y la capacidad de adaptarse a requisitos cambiantes de los clientes conforme las prácticas de manejo ganadero y los diseños de instalaciones continúan avanzando en respuesta a condiciones cambiantes del mercado y requisitos regulatorios.

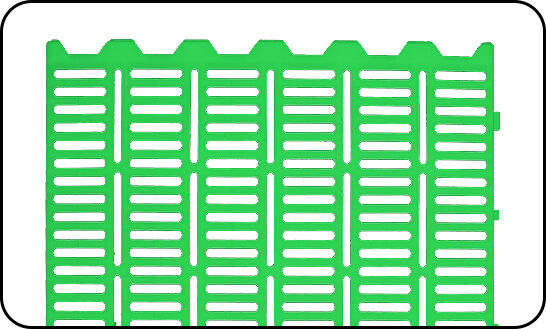

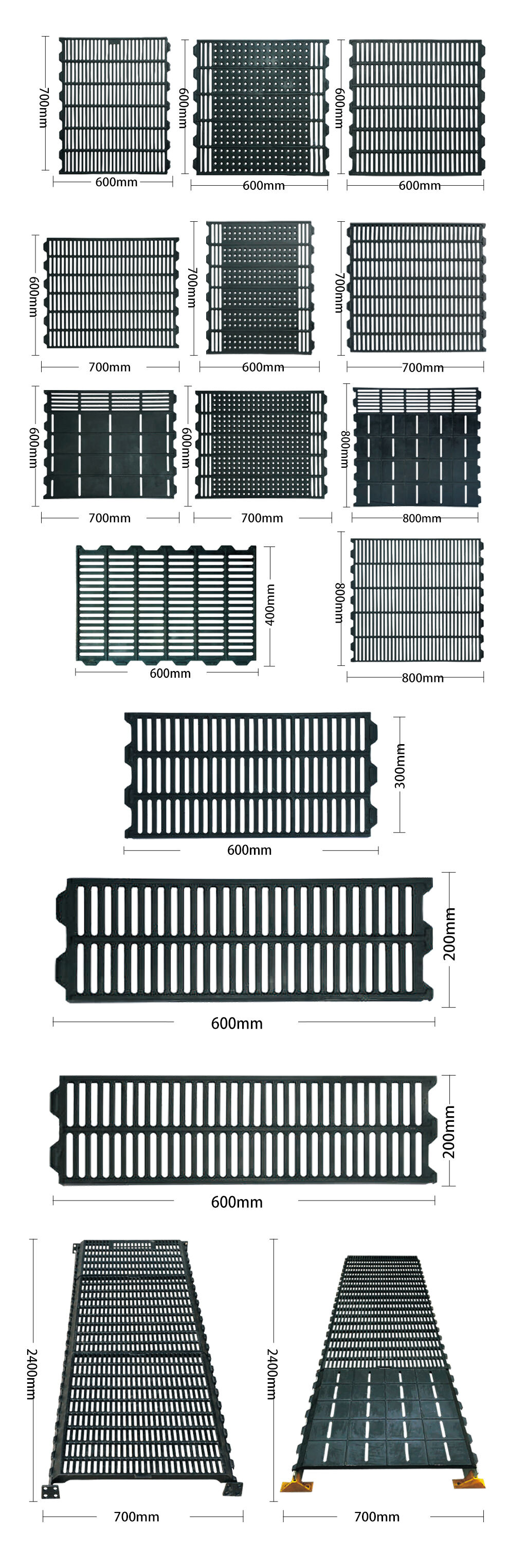

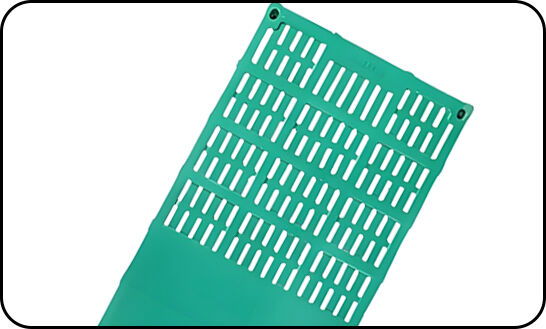

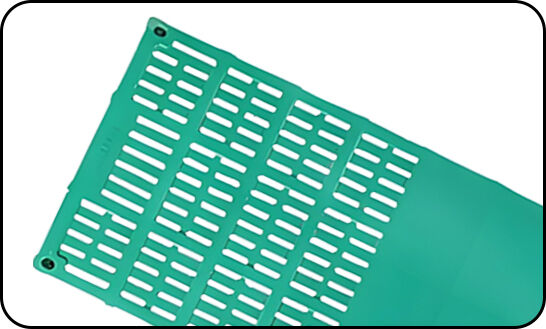

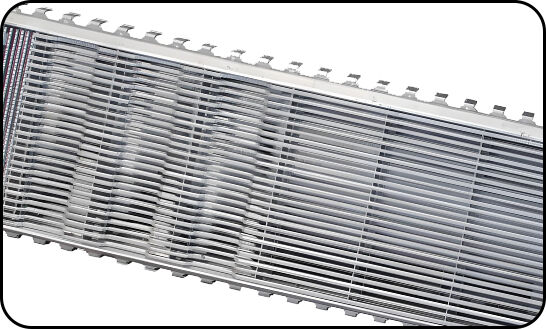

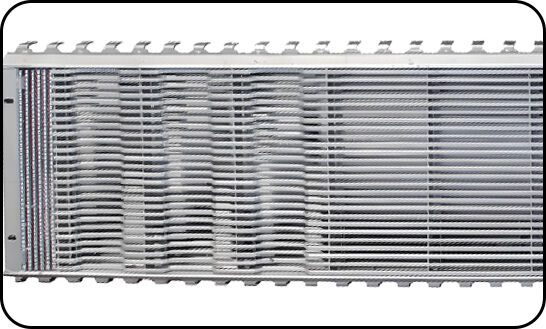

Piso de tablillas de polipropileno PP para granja porcina Tamaño personalizado

-

Material Duradero y de Alta Calidad – Fabricado con polipropileno (PP) resistente y flexible que no se corroe y es duradero para uso prolongado.

-

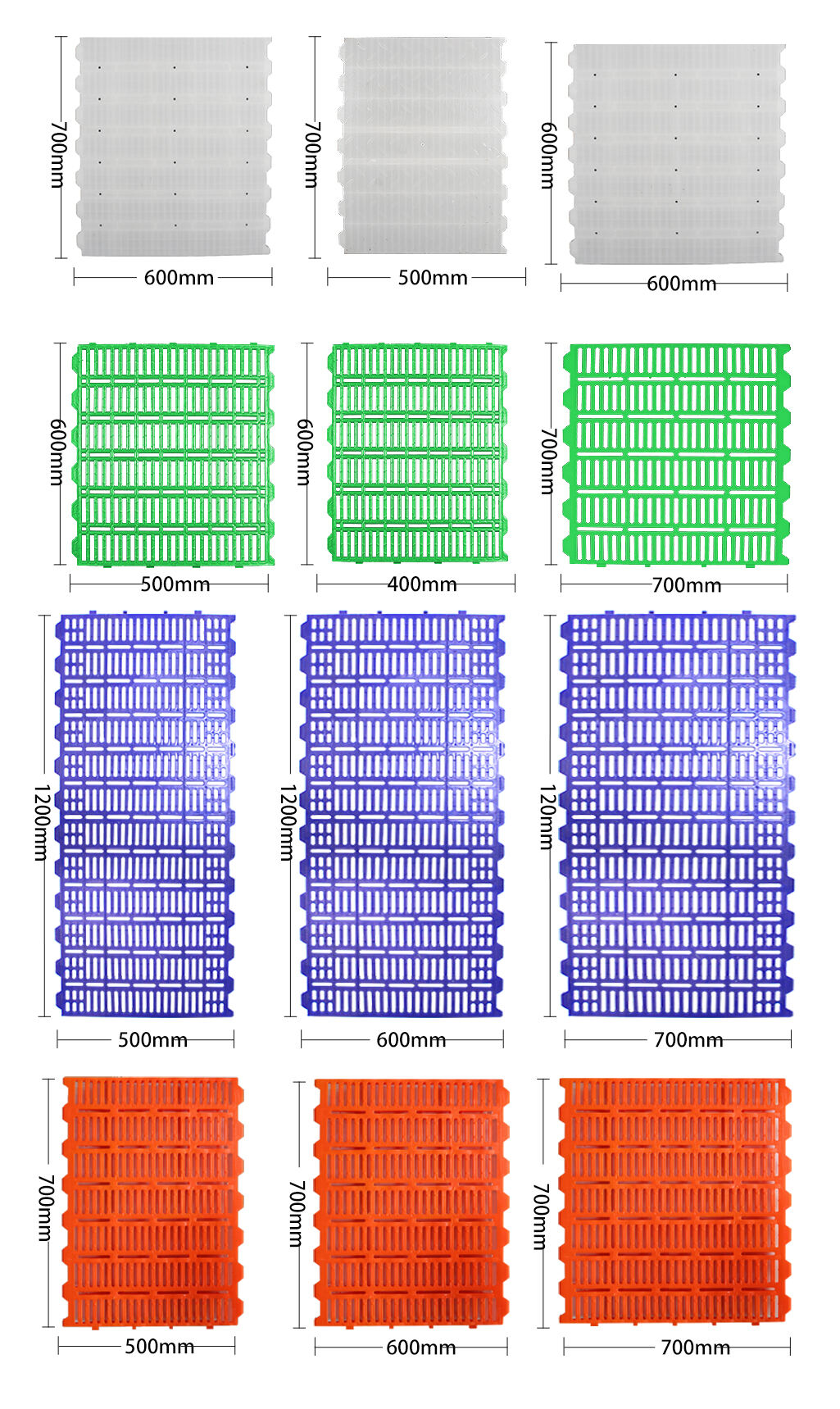

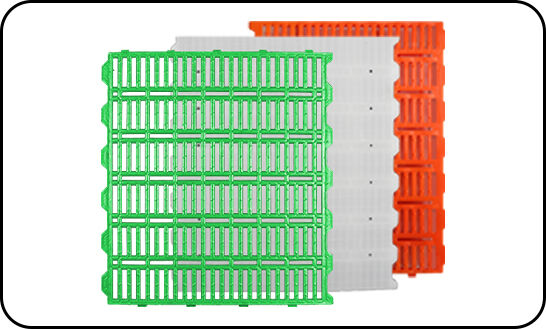

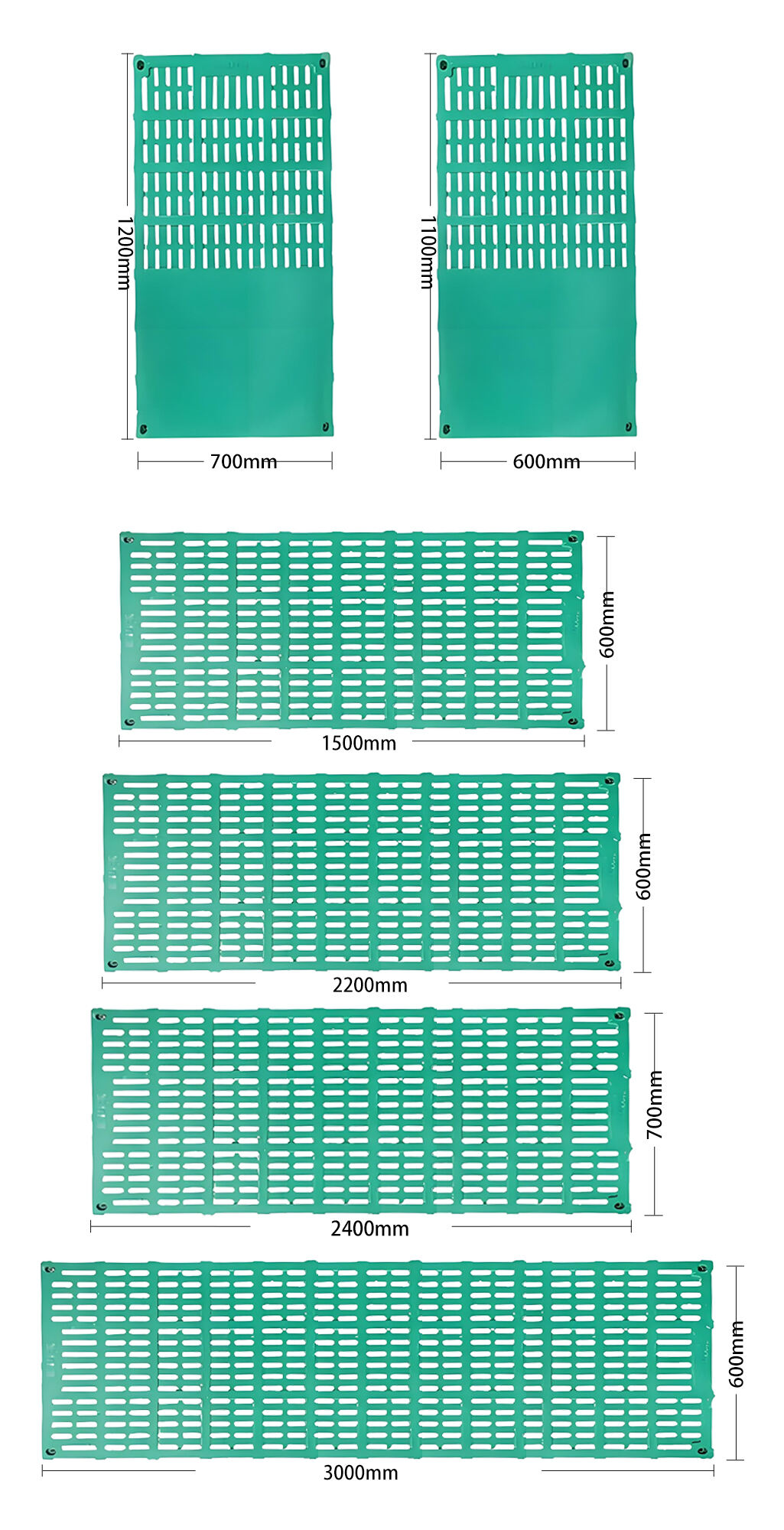

Ajuste personalizable y versátil – Disponible en diferentes tamaños y diseños para adaptarse a distintas distribuciones de instalaciones porcinas y etapas de crecimiento.

-

Diseño seguro y amigable para los animales – Superficie antideslizante, bordes suaves y esquinas redondeadas reducen lesiones y garantizan comodidad para los cerdos.

-

Drenaje eficiente y limpieza – El espaciado optimizado entre listones favorece la rápida eliminación de desechos y ayuda a mantener un ambiente higiénico.

-

Ligero y fácil de instalar – Fácil de manejar, limpiar y reposicionar, ahorra mano de obra y apoya una operación eficiente de la granja.

- Descripción general

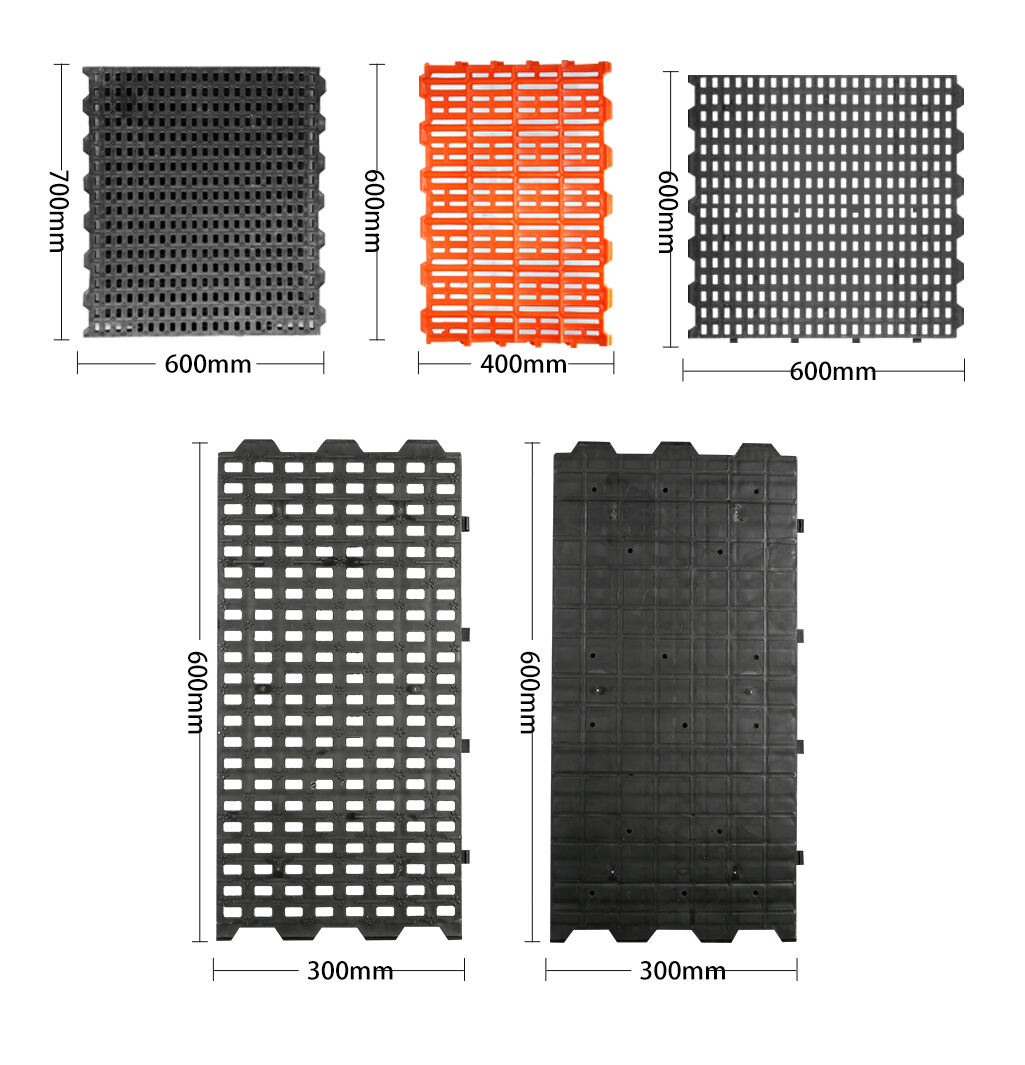

- Tipo 1

- Tipo 2

- Tipo 3

- Tipo 4

- Tipo 5

- Productos recomendados

Descripción

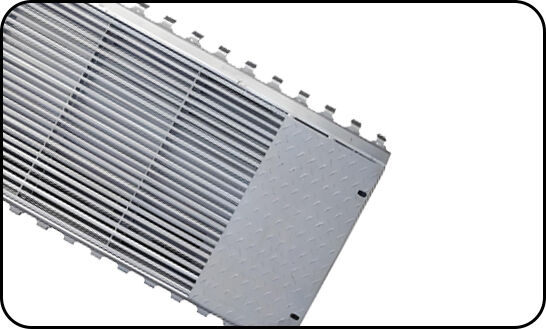

El suelo plástico para cerdos Wanqing está fabricado con moldeo por inyección de alta tecnología utilizando polipropileno copolímero virgen, ofreciendo una solución duradera y de larga vida útil para crías de cerdos y establos de parto. Disponible en múltiples configuraciones y tamaños de rejilla, se adapta fácilmente a proyectos de construcción nueva o remodelación de establos, garantizando flexibilidad para distintas configuraciones.

En comparación con los suelos tradicionales de metal, nuestro suelo plástico para cerdos ofrece una mejor conductividad térmica, lo que facilita y abarata el mantenimiento de un ambiente cálido y confortable para los cerditos. Esto contribuye a mejorar el bienestar de los lechones y favorece un crecimiento más saludable.

El diseño entrelazado está respaldado por nuestro sistema de vigas de fibra de vidrio y patas de soporte opcionales, proporcionando estabilidad y resistencia en cualquier instalación. Además, la superficie lisa de plástico es fácil de limpiar con una hidrolavadora y sanitizar, ayudando a los productores a mantener una excelente higiene y bioseguridad para los cerditos con sistemas inmunológicos en desarrollo, creando así un entorno inicial ideal para los lechones.

Certificado

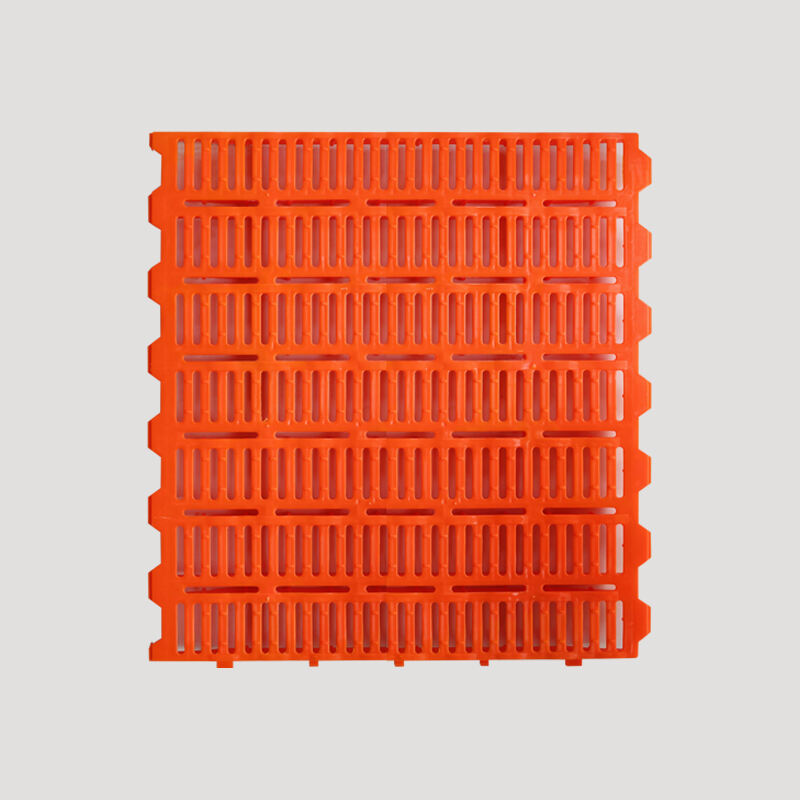

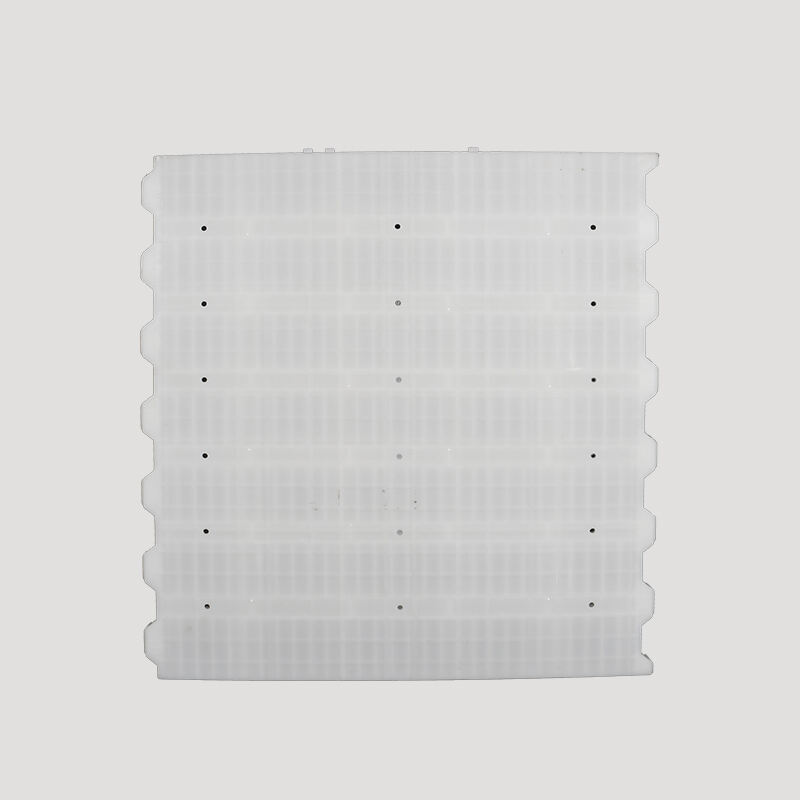

Tipo 1

|

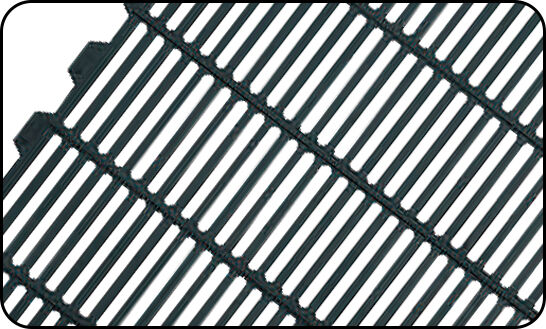

Ligero y Flexible |

|

Reducción de vibraciones y ruido, antideslizante, sin bordes ni esquinas afiladas |

|

|

Orificio de drenaje, sin heces, seguro e higiénico |

|

Diversas especificaciones, corrosión resistencia y resistencia al envejecimiento |

|

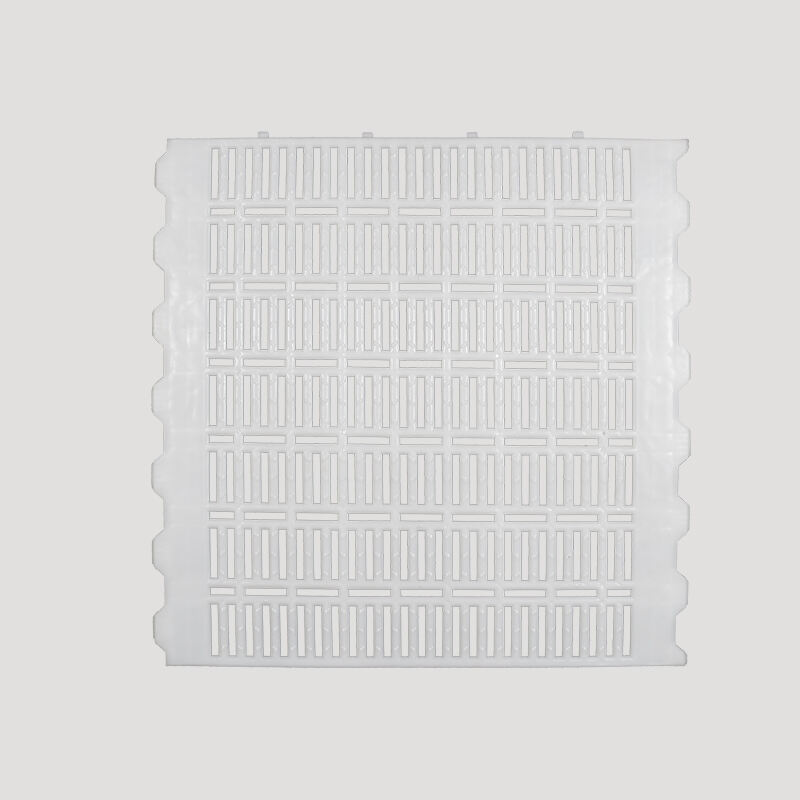

Tipo 2

|

Material de alta resistencia |

|

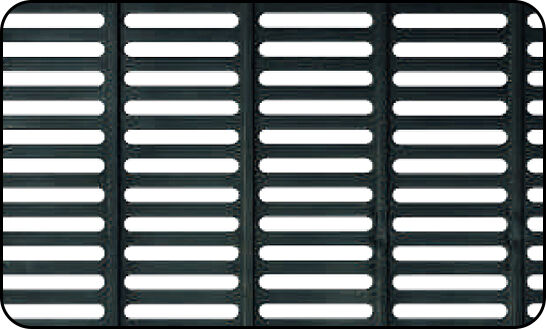

Alta calidad antideslizante y excelente rendimiento de amortiguación |

|

|

Diseño antibacteriano, limpieza completa |

| Diseño estructural reforzado |  |

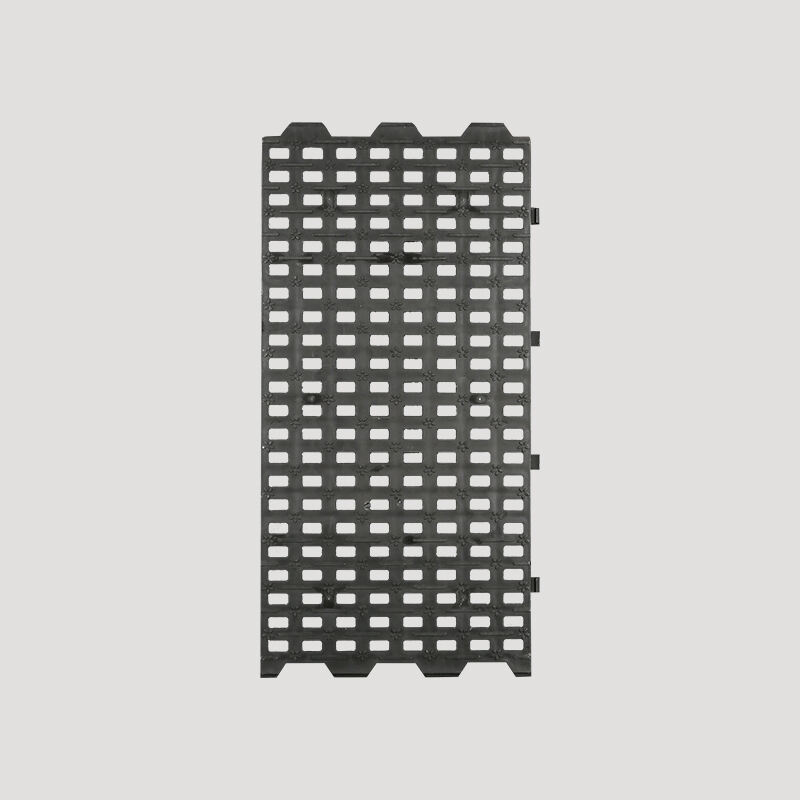

Tipo 3

|

Buenas propiedades químicas y resistencia a la corrosión |

|

Bordes reforzados, resistentes capacidad de carga |

|

|

Orificio de drenaje, sin heces, seguro e higiénico |

|

Patrón antideslizante en la superficie combinado con tratamiento de prensado en arco para evitar que el ganado resbale |

|

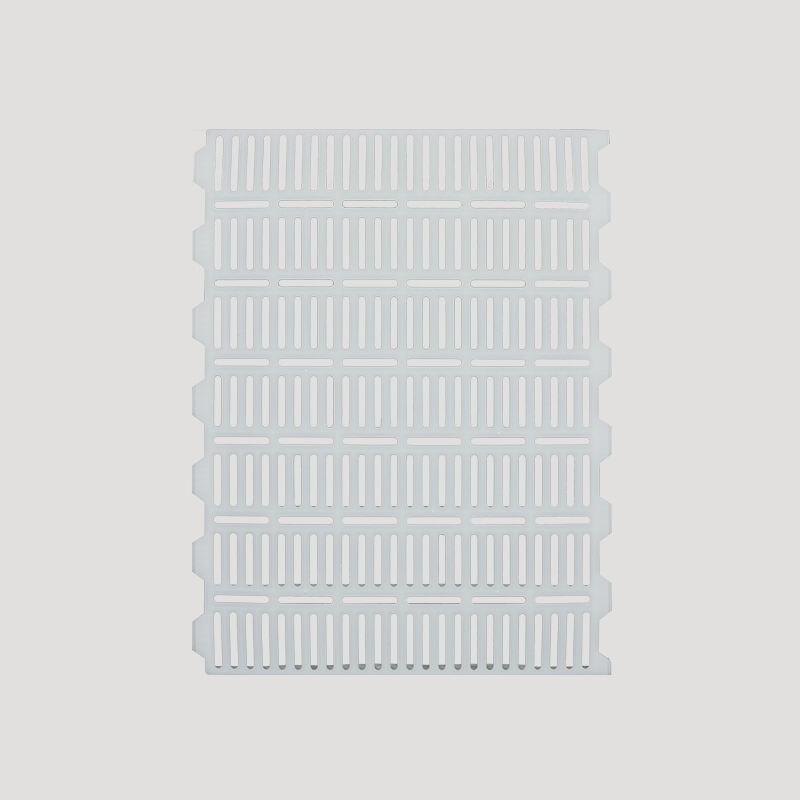

Tipo 4

|

Alta resistencia, resistencia a la corrosión |

| Excelente rendimiento antideslizante |  |

|

Eficiente drenaje de heces, fácil de Limpiar |

| Fácil instalación y larga vida útil |  |

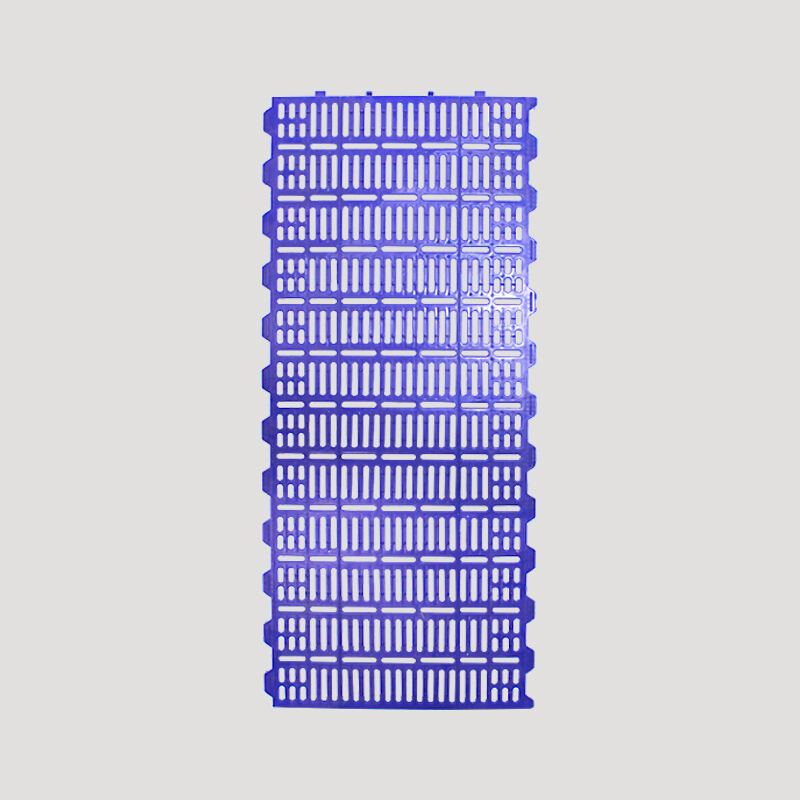

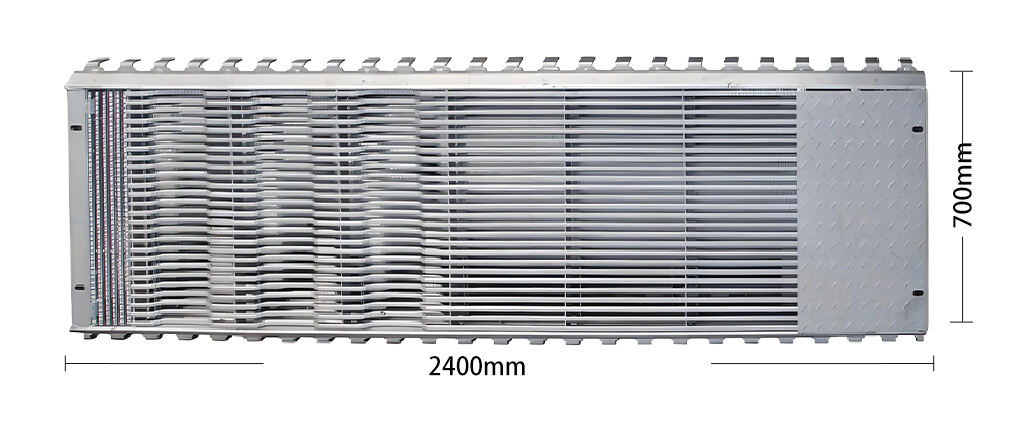

Tipo 5

|

Alta capacidad de carga, estable y Duradero |

| Fuerte facilidad de mantenimiento |  |

|

Fuga eficiente de heces y instalación fácil |

| Ventilación y transpirabilidad |  |