Understanding Slat Floors and Their Core Applications

Slat Floors 101: Core Features and Construction

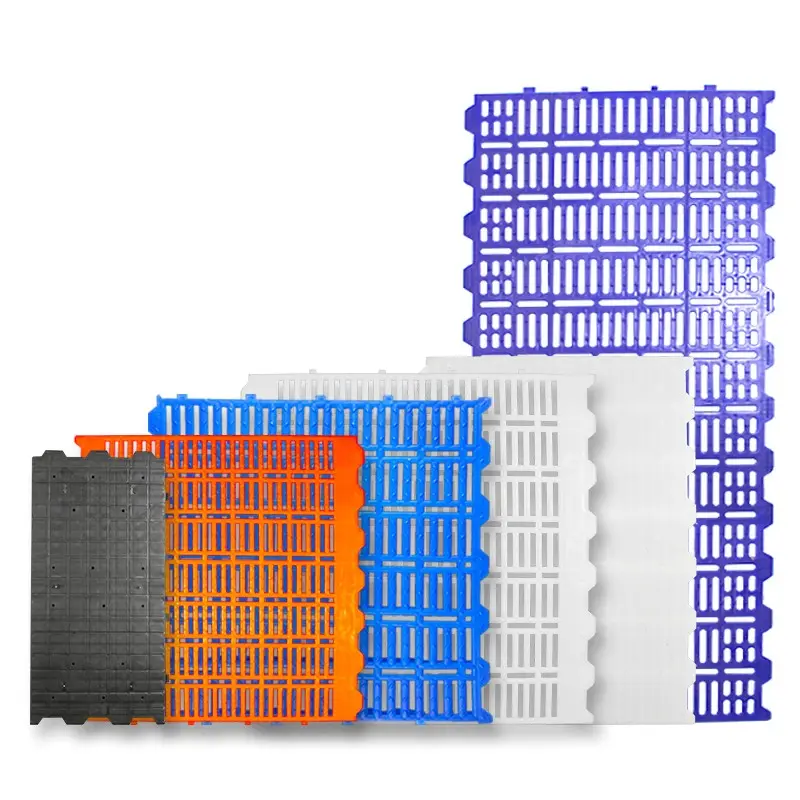

Slat floors—defined by their spaced-slat design—are engineered for superior drainage and ventilation, making them indispensable in industries like agriculture and manufacturing where these attributes are critical. Constructed from plastic, concrete, or metal, the choice of material directly impacts the floor’s efficiency and suitability for specific tasks. Each material brings unique advantages: plastic slats stand out for their lightweight design and easy cleaning; metal slats offer exceptional sturdiness; and concrete slats remain a popular choice for heavy-duty applications due to their unbeatable durability and longevity.

A deeper look at their construction reveals that slat dimensions and spacing can be fully customized to meet specific needs, greatly expanding their applicability across diverse fields.

Common Industrial & Agricultural Use Cases

Slat floors play a pivotal role in both animal welfare and farm operational efficiency, as they significantly influence livestock handling and behavior. Their robust drainage capabilities ensure optimal hygiene for livestock—an essential factor in animal health—while also simplifying large-scale waste disposal on farms, streamlining daily operations. In industrial settings, slat floors are favored for their ability to withstand heavy machinery use, long service life, and low maintenance requirements. This makes them the go-to choice for industries where cleanliness and structural strength are top priorities.

Tailoring Slat Floors to Your Specific Application

Livestock Farming: Prioritizing Animal Safety and Welfare

Slat floors are vital in animal husbandry for safeguarding animal safety and comfort. Key design requirements include smooth surfaces free of sharp edges and properly sized openings to prevent injuries—standards aligned with guidelines from animal welfare organizations like The Humane Society, which mandates appropriate flooring to minimize livestock harm. Selecting the right material and optimizing slat spacing are critical steps to meeting these welfare standards and ensuring the unique needs of each livestock type are fulfilled.

Poultry Housing: Flooring Considerations for Health & Productivity

For poultry housing, slat floors must excel at waste management while reducing respiratory issues in birds. The ideal design should enable easy cleaning and natural drainage to avoid ammonia buildup—a major threat to poultry lung health. Understanding species-specific needs is essential: for example, the floor’s load-bearing capacity must match the birds’ weight, and the surface should be comfortable for walking (abrasive textures are avoided to prevent leg injuries). These considerations directly influence material selection and floor suitability, ultimately impacting poultry health and farm productivity.

Industrial Drainage: Slat Systems for Safe Work Environments

In industrial settings, slat systems are critical for effective drainage, reducing hazards from hazardous materials and creating safer workplaces. These systems efficiently channel fluids away from work areas, minimizing slip risks and contamination. Real-world case studies—such as factory installations—demonstrate how slat floors enhance workplace health and safety. Their durability and easy sanitization make them ideal for environments with heavy vehicle and machinery use that demand both robustness and cleanliness. Choosing the right slat system ensures industries meet all drainage requirements while boosting overall workplace safety.

Comparing Slat Floor Construction Materials

Plastic Slats: Lightweight, Corrosion-Resistant Solutions

Plastic slat floors offer a practical, cost-effective option—especially for humid environments. Resistant to wear and maintenance-free, they reduce the frequency of replacements and repairs. Their lightweight design simplifies handling and speeds up installation, cutting down on labor hours and downtime. Plastic slats are particularly advantageous in scenarios requiring frequent replacements or modifications, as they offer flexibility not found in heavier materials like concrete or metal.

Concrete Slats: Heavy-Duty, Long-Lasting Installations

Concrete slats are the gold standard for heavy-load applications, such as supporting large tractors or cattle. While upfront costs may be higher, their exceptional durability and minimal maintenance needs translate to long-term cost savings. They provide peace of mind for those seeking a permanent flooring solution that will last for years, significantly reducing the need for frequent replacements.

Metal Grating: High-Strength for Industrial Demands

Metal grating slats are engineered to withstand the harshest environments, delivering unmatched performance and safety for tough industrial applications. Their open-grid design enables unobstructed liquid flow, making them essential for wet environments where traction is critical. Boasting superior strength and durability, metal grating slats offer a long-lasting solution for businesses needing heavy-duty flooring without compromising on drainage or functionality.

Evaluating Load-Bearing Capacity for Long-Term Durability

Weight Capacity Standards for Different Livestock Species

When selecting slat floors for livestock, understanding species-specific weight capacities is non-negotiable. Each animal type exerts different stress on the floor—for example, pork and beef cattle have varying weight requirements, so their flooring specifications differ. Agricultural standards serve as crucial references, helping ensure the floor’s load-bearing capacity protects both livestock and users while preventing catastrophic material failure. Adhering to these standards avoids accidents and extends the floor’s service life.

Machinery Traffic: Critical Considerations for Industrial Floors

In industrial facilities, slat floor durability must account for heavy machinery traffic to prevent failures. The significant loads exerted by moving heavy equipment require rigorous load testing. Consulting engineering guidelines is essential to accurately calculate load requirements and specify flooring that meets the facility’s unique needs. This proactive approach improves decision-making and safeguards the floor’s long-term performance and safety.

Prioritizing Hygiene & Maintenance Efficiency

Slat Design Features That Simplify Cleaning

Slat floor structure is a key factor in maintaining hygiene and simplifying cleaning. Smooth, angled surfaces and edges eliminate waste buildup zones, making cleaning faster and more thorough while slashing labor and maintenance costs. These design improvements streamline operations, freeing up resources to focus on core tasks by minimizing cleaning time. For animal farming facilities in particular, prioritizing cleaning-friendly features in slat floor selection yields significant benefits, including better hygiene, improved working conditions, and enhanced animal health.

Integrating Waste Management into Floor Design

In animal housing facilities, integrating waste management into slat floor design is non-negotiable for maintaining cleanliness. These integrated systems seamlessly channel waste toward disposal and treatment facilities, ensuring hygiene and reducing pollution risks. Facilities with well-integrated systems operate more efficiently, a testament to the value of this design approach. Leading suppliers to large-scale agricultural operations now offer flooring systems tailored to waste disposal processes, highlighting how integration boosts operational value.

By emphasizing waste handling in slat floor design, farms can achieve higher hygiene standards, easier maintenance, and safer living conditions for livestock. Decisions to improve slat floor systems in poultry farming, for example, should always be based on welfare recommendations specific to slat floor setups.

Antimicrobial Coatings: Elevating Sanitation Standards

Antimicrobial coatings represent a key advancement in slat floor technology, inhibiting bacterial growth—a critical feature for food safety systems in animal agriculture. These coatings enhance sanitary conditions by preventing bacterial growth and spread, protecting both animal welfare and product quality. Scientific research confirms that antimicrobial interventions are effective tools for improving facility sanitation and resilience against microbial threats. By adopting these coatings, facilities can significantly upgrade their hygiene standards, safeguarding both livestock and animal products from bacterial contamination.

FAQ

What are slat floors primarily used for in agriculture?

In agriculture, slat floors are mainly used to streamline waste management and enhance hygiene in livestock farming, creating a safer, healthier environment for animals.

What materials are commonly used for slat floors?

The most common materials for slat floors are plastic, concrete, and metal—each with distinct benefits: plastic offers lightweight convenience, concrete delivers heavy-duty durability, and metal provides exceptional strength.

Why is drainage important in slat floor systems?

Effective drainage prevents waste accumulation, which is critical for maintaining cleanliness and reducing contamination risks in both industrial and agricultural settings.

How do antimicrobial coatings benefit slat floors?

Antimicrobial coatings inhibit bacterial growth, significantly boosting hygiene—an essential advantage in agricultural settings where food safety and animal welfare are top priorities.