تمثل أرضية الخنازير المشبكة بمقاسَي ٤٠×٦٠ سم و٦٠×٦٠ سم لمعدات تربية الماشية حلاً هندسيًّا متطوّرًا صُمِّم خصيصًا لتلبية المتطلبات الصارمة لمزارع تربية الخنازير الحديثة، وتقدّم لمشغّلي المزارع وموزّعي معدات الزراعة نظام أرضياتٍ موثوقٍ يجمع بين المتانة والوظيفية واعتبارات رفاهية الحيوان في حزمةٍ مهندسةٍ بدقة. ويُعالَج هذا الحل المتخصّص لأرضيات تربية الماشية الحاجة الحرجة إلى إدارة النفايات بشكلٍ سليم وتحقيق الظروف الصحية الملائمة في مرافق إيواء الخنازير، مع توفير المتانة الإنشائية اللازمة لتحمل أوزان الحيوانات المختلفة والمتطلبات التشغيلية المتنوعة عبر مراحل الإنتاج المختلفة. وتمكّن التكوينة الثنائية للأحجام من تكيّف النظام مع تخطيطات المرافق المتنوعة وتفضيلات الإدارة، ما يسمح لمشغّلي المزارع باختيار الأبعاد الأنسب وفقًا لتخطيطات الأقفاص المحددة لديهم، ومتطلبات كثافة الحيوانات، وسير العمليات التشغيلية، وبالتالي تعظيم استغلال المساحة وراحة الحيوان على امتداد دورة الإنتاج بأكملها. وتشمل عمليات التصنيع لهذه الأنظمة من الأرضيات المشبكة عادةً تقنيات دقيقة للقالبة أو الصب التي تضمن ثبات الأبعاد وخصائص السطح، باستخدام مواد تم اختيارها لمقاومتها للبيئات الزراعية المسببة للتآكل، والعوامل الكيميائية المستخدمة في عمليات التنظيف، والإجهادات الميكانيكية الناتجة عن حركة الحيوانات المستمرة وعمليات الصيانة. ويتضمّن مبدأ التصميم المشبك حسابات دقيقة لأبعاد الفتحات لتسهيل تصريف النفايات بكفاءة وتوفير التهوية المناسبة، مع منع إصابات حوافر الحيوانات وتوفير قاعدة ثابتة للحيوانات بمختلف أحجامها، مما يدلّ على الاعتبارات الهندسية المتطوّرة التي تميّز معدات تربية الماشية الاحترافية عن مواد البناء الأساسية. وتُحسَّن معالجات السطح وعمليات التشطيب عادةً لتحقيق التوازن الأمثل بين مقاومة الانزلاق لسلامة الحيوان والخصائص الناعمة التي تيسّر عمليات التنظيف والتعقيم الشاملة، مما يضمن أن يسهم نظام الأرضيات إسهامًا إيجابيًّا في نظافة المرفق العامة وبروتوكولات إدارة صحة الحيوان. ومن منظور الشراء الدولي بين الشركات (B2B)، فإن هذه أنظمة أرضيات تربية الماشية تخدم وكلاء معدات الزراعة، والمقاولين المتخصصين في إنشاء المزارع، ومطوري مرافق تربية الماشية الذين يحتاجون إلى موردين موثوقين قادرين على ضمان جودة ثابتة في المشاريع الضخمة، مع الحفاظ على مكانتهم التنافسية في الأسواق العالمية التي تكتسب فيها معايير رفاهية الحيوان ومعايير كفاءة الإنتاج أهمية متزايدة. ويمتد تنوع هذه الحلول للأرضيات ليشمل تطبيقات تتجاوز تربية الخنازير التقليدية، حيث تجد استخدامًا في مختلف عمليات تربية الماشية التي تتطلب إدارة فعّالة للنفايات، وتهوية مناسبة، وراحة للحيوان، مثل المرافق المتخصصة لتربية الحيوانات، ووحدات الحجر الصحي، والمرافق البحثية التي تتطلّب تحكّمًا بيئيًّا ورصدًا دقيقين. ويمثّل الاتساق في الجودة جانبًا أساسيًّا في تصنيع معدات تربية الماشية الاحترافية، حيث يؤثر الدقة في الأبعاد، وسلامة المادة، وتوحّد تشطيب السطح تأثيرًا مباشرًا على نجاح التركيب الفوري والأداء التشغيلي الطويل الأمد، ما يستلزم عمليات تصنيع قوية وأنظمة شاملة لمراقبة الجودة تضمن توافق كل وحدة مع المعايير الصارمة المطلوبة في عمليات تربية الماشية التجارية. وتكتسب اعتبارات التعامل مع المنتجات الموجّهة للتصدير أهمية خاصة بالنسبة للمشترين الدوليين الذين يجب أن ينسّقوا سلاسل لوجستية معقّدة مع الحفاظ على سلامة المنتج طوال مراحل النقل والتخزين والتركيب، ما يتطلّب موردين يدركون التحديات الفريدة لتوزيع معدات الزراعة، ويمكنهم توفير حلول تغليف مناسبة تحمي المنتج من التلف مع تحسين كفاءة الشحن وفعاليته من حيث التكلفة. وتشمل إمكانات التخصيص في هذه الفئة من المنتجات جوانب مختلفة مثل التعديلات البُعدية لتكيّف النظام مع تخطيطات المرافق المحددة، والتباينات في نسيج السطح لتحسين راحة الحيوان وسلامته، وخيارات الألوان التي قد تخدم تفضيلات تشغيلية أو جمالية مع الحفاظ على الخصائص الأداء الأساسية الضرورية لتطبيقات تربية الماشية. ويركّز النهج التعاوني في شراكات التصنيع حسب الطلب (OEM) والتصنيع حسب التصميم (ODM) في قطاع معدات تربية الماشية على الاستشارة الفنية والتحسين المُوجَّه حسب التطبيق، ما يمكّن المشترين من العمل بشكل وثيق مع المصنّعين لتطوير حلول تلبّي متطلبات التشغيل الفريدة، أو احتياجات الامتثال التنظيمي، أو التحديات المتعلقة بالدمج مع البنية التحتية الحالية للمرافق وأنظمة الإدارة. وتمتد اعتبارات التوافق بين التغليف واللوجستيات لما وراء متطلبات الحماية الأساسية لتشمل التعبئة الفعّالة على المنصات، وتحسين استغلال حاويات الشحن، وإجراءات المناولة التي تقلّل من متطلبات العمالة أثناء التركيب، مع ضمان وصول المنتجات إلى مرافق الوجهة في أفضل حالة ممكنة، وجاهزيتها للنشر الفوري في البيئات التشغيلية. وتعكس توقعات التعاون طويل الأمد مع المورّدين في قطاع معدات تربية الماشية الطبيعة المستمرة لعمليات المزارع والحاجة إلى الوصول الثابت لمكونات الاستبدال، والدعم الفني، وقدرات التوسّع مع نمو العمليات أو تطوّرها، ما يضع المصنّعين الموثوقين في موقع شركاء استراتيجيين بدلًا من مورّدين تعاقدِيّين ضمن نسيج سلسلة التوريد الزراعية.

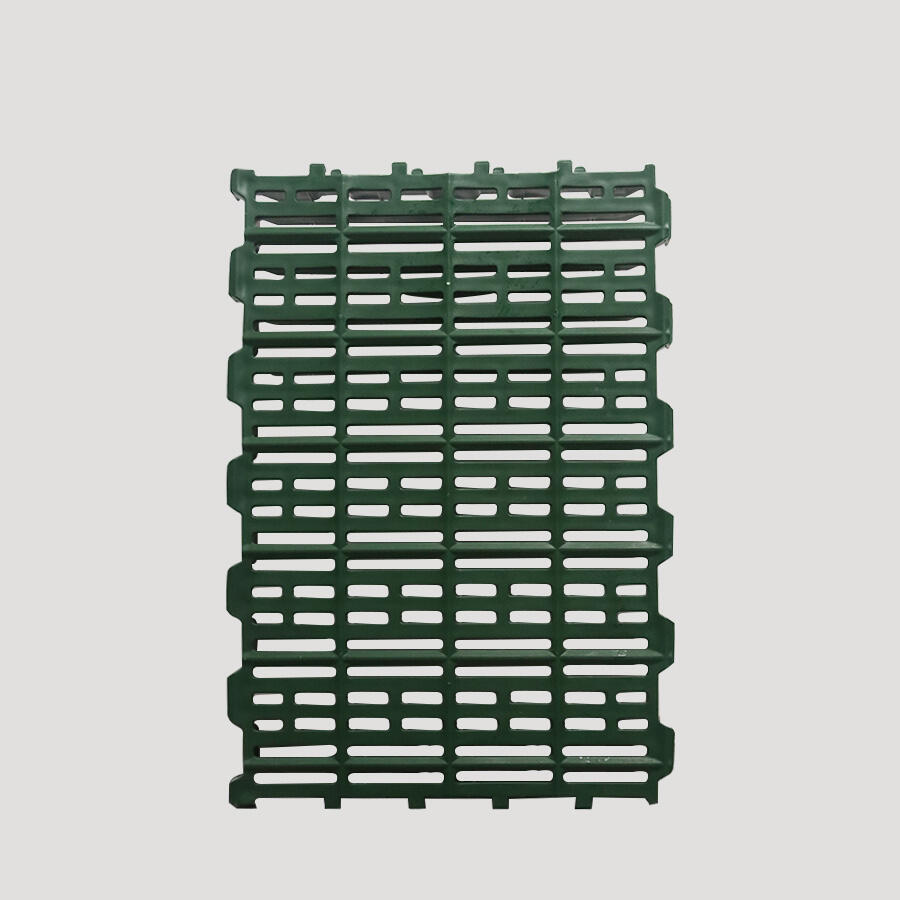

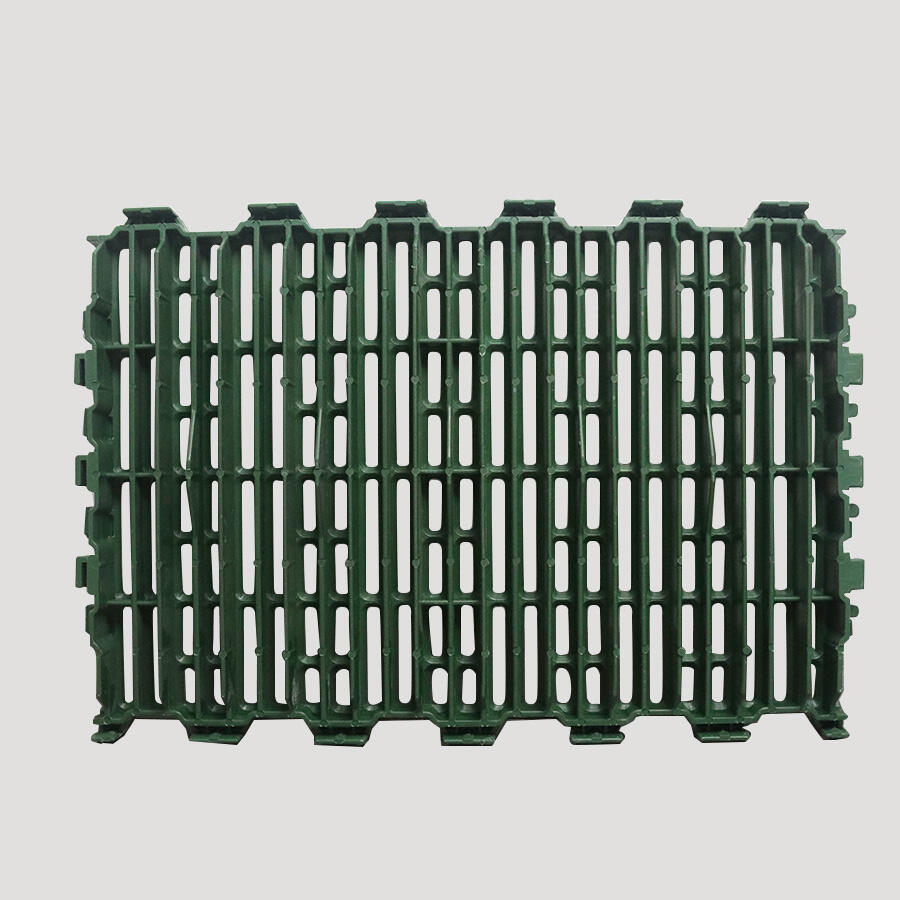

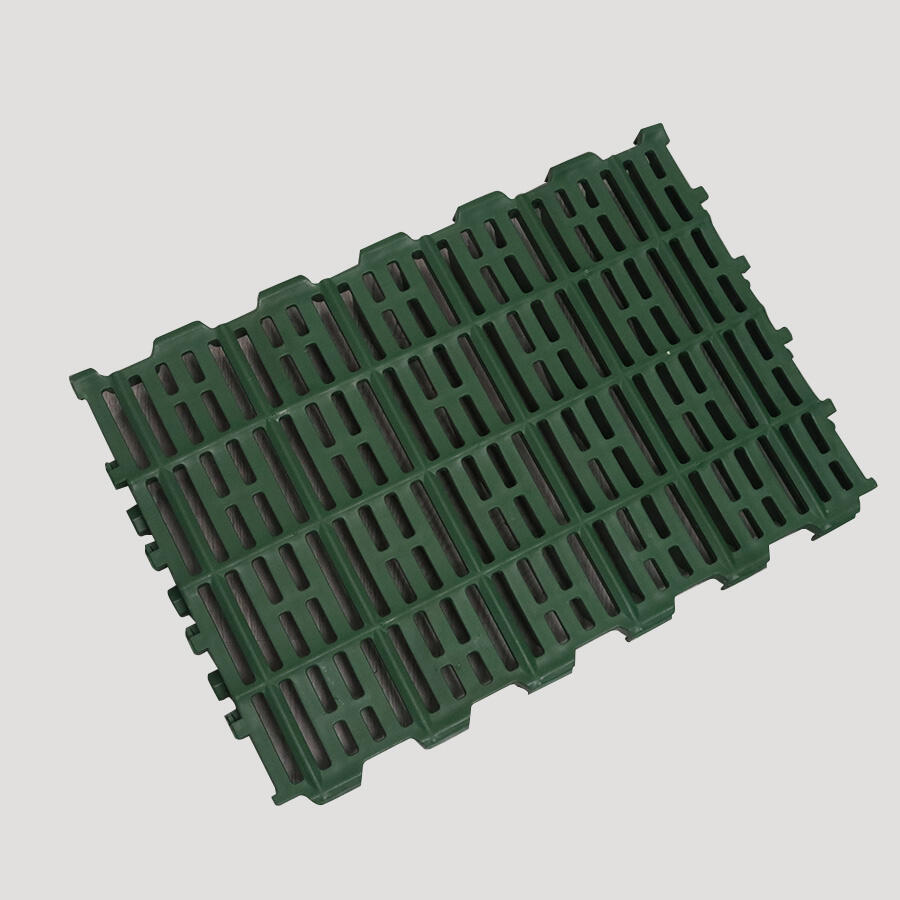

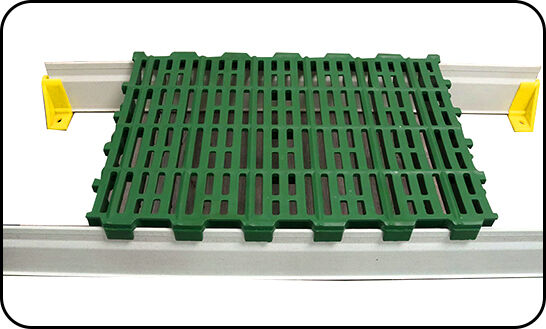

أرضية خرسانية مُثَلَّثَة للخنازير 40*60 سم، 60*60 سم، لمعدات تربية الماشية

-

مادة PP متينة – مصنوعة من بولي بروبيلين عالي الجودة، قوية ومقاومة للتآكل وطويلة الأمد.

-

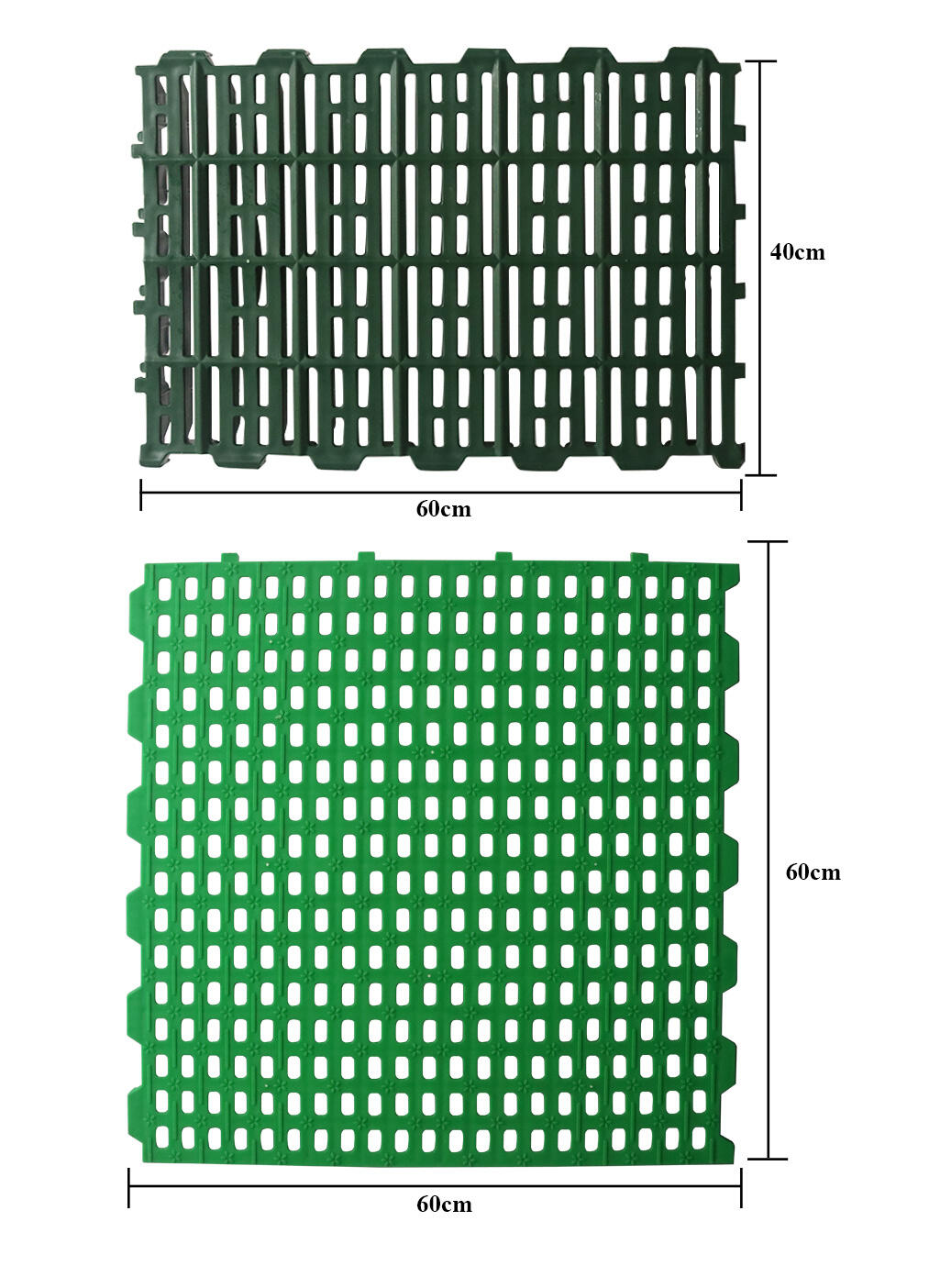

خيارات الأحجام المثلى – متوفرة بمقاسات 40×60 سم و60×60 سم لتتناسب مع مختلف تخطيطات الحظائر وإعدادات المعدات.

-

التصميم النظيف – هيكل مُثَلَّث يضمن تصريف الفضلات بسرعة، مما يحافظ على جفاف الحظائر ويقلل من نمو البكتيريا.

-

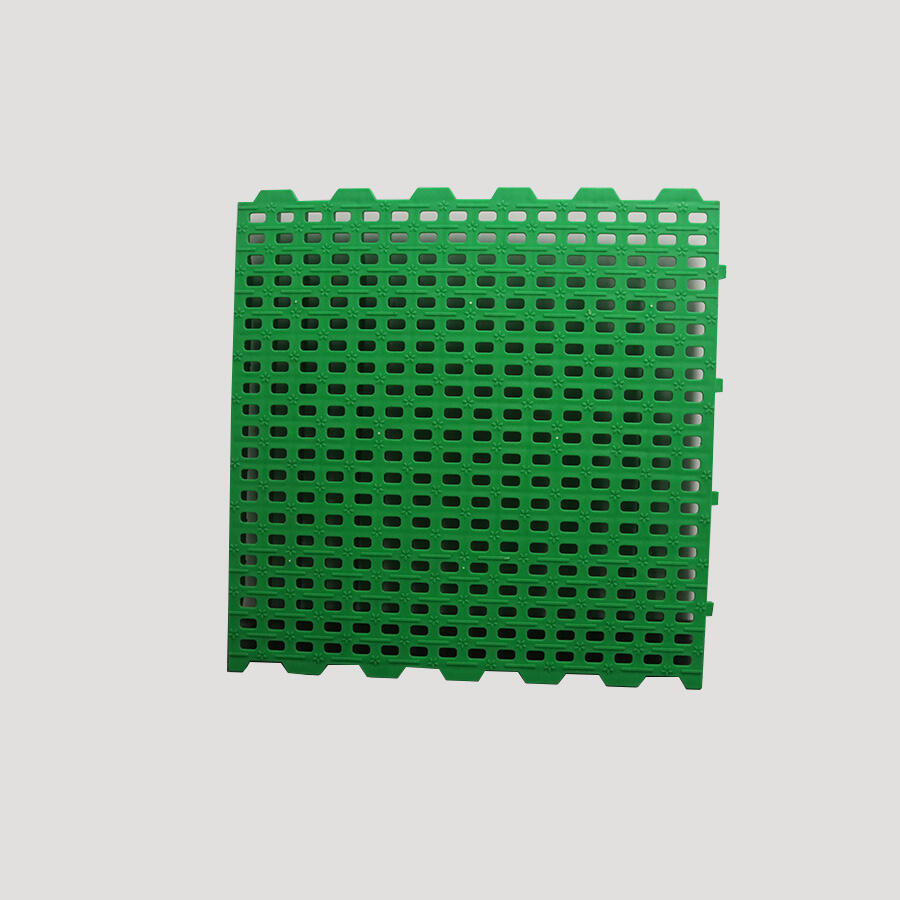

سطح صديق للحيوان – حواف ناعمة ومُدَوَّرة تحمي أقدام الخنازير الصغيرة وتعزز الراحة العامة.

-

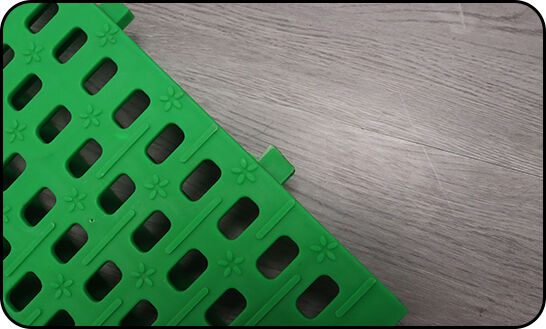

تركيب وتنظيف سهلين – تصميم متشابك للتركيب السريع والتنظيف بضغط المياه بسهولة.

- نظرة عامة

- الحجم

- التفاصيل

- المنتجات الموصى بها

وصف

تم تصميم أرضية WQXM البلاستيكية لتوفير حل متين وطويل الأمد لتركيبات خنازير المهد وحظائر الولادة. يتم تصنيع هذه الأرضية باستخدام عملية صب متطورة بتقنية الحقن باستخدام بوليمر البولي بروبيلين المركب عالي الجودة، مما يضمن قوة استثنائية ومتانة وطول العمر، مما يجعلها مثالية لكل من مشاريع البناء الجديدة وإعادة تأهيل الحظائر.

تتوفر أرضيتنا بأحجام وأنماط شبكات متعددة، ويمكن تعديلها لتتناسب مع مختلف تصميمات المباني، لتلبية احتياجات عمليات تربية الخنازير الحديثة. وعلى عكس الأرضيات المعدنية التقليدية، فإن أرضيات الخنازير البلاستيكية التي نوفرها تتميز بموصلية حرارية أفضل، مما يجعلها أكثر سهولة وفعالية من حيث التكلفة في الحفاظ على بيئة دافئة ومريحة للخنازير الصغيرة.

الأرضية سهلة التنظيف بالغسالة الكهربائية والتعقيم، مما يقلل من مخاطر الأمراض ويوفر مساحة نظيفة وصحية للخنازير ذات الأنظمة المناعية الناشئة.

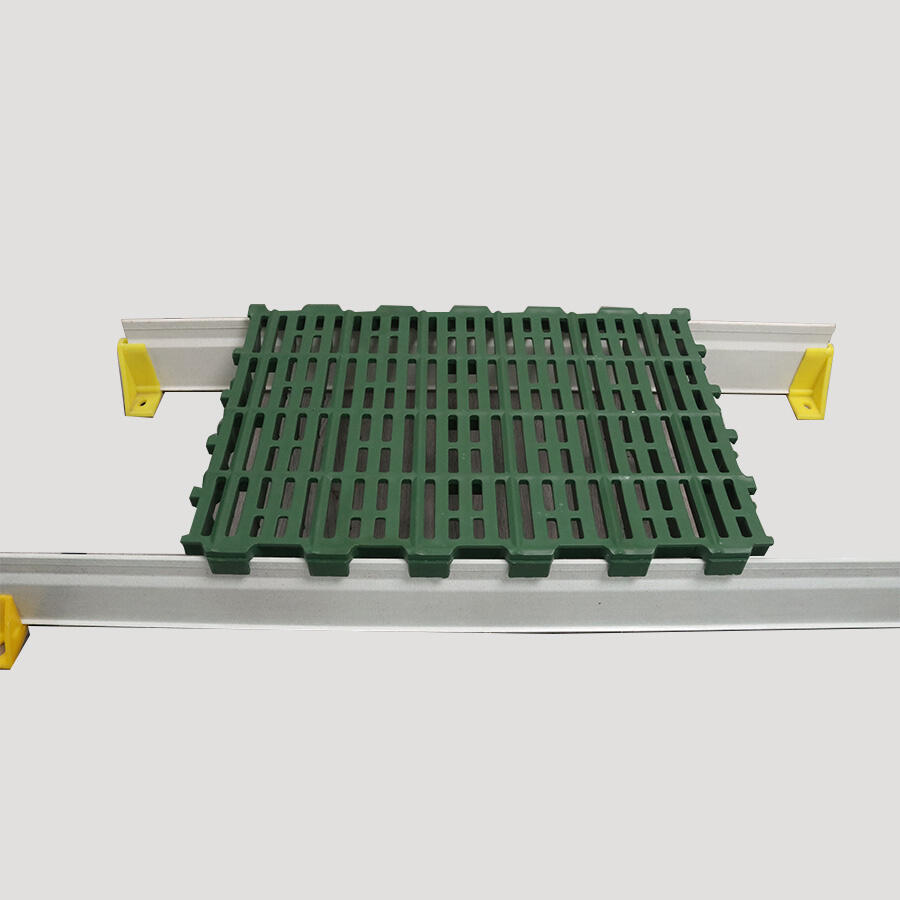

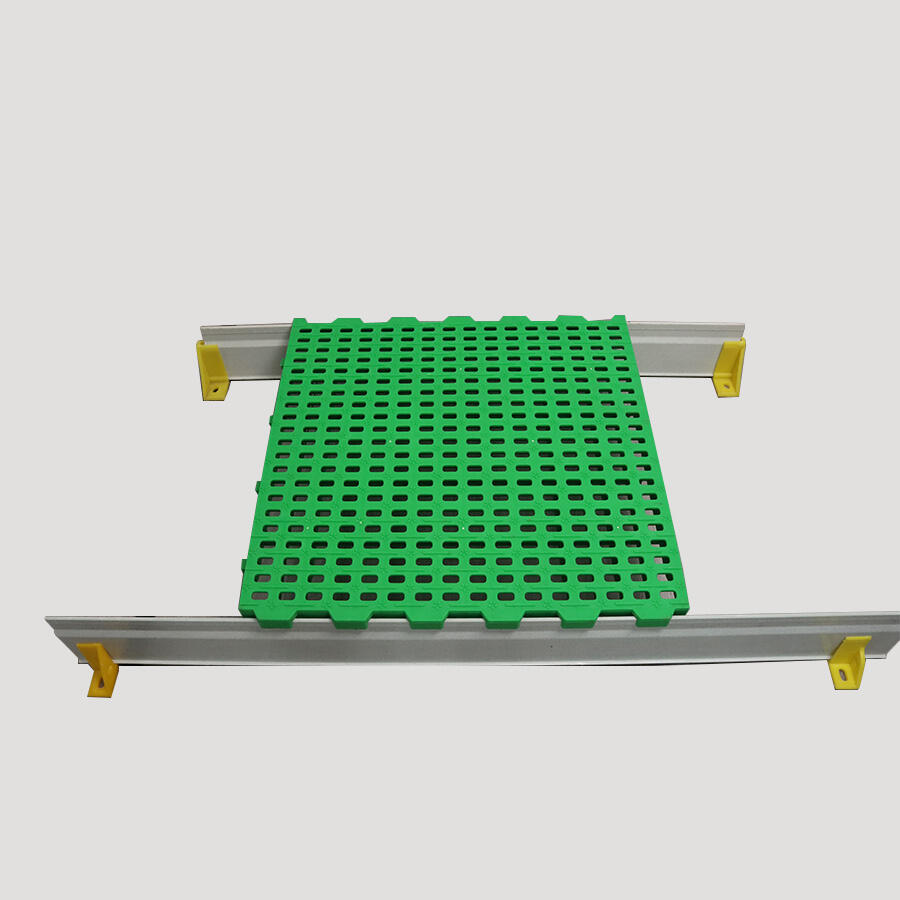

بالإضافة إلى ذلك، فإن دعائم العارضة لدينا وأرجل الدعم الاختيارية توفر تدعيمًا متينًا وموثوقًا، مما يضمن استقرار الأرضيات في أي تصميم لحظيرة.

بفضل تصميمها المبتكر وجودة المواد المتفوقة، تقدم هذه الأرضية البلاستيكية المتشابكة حلاً آمنًا وصحيًا وفعالًا لمُنتجي الخنازير لدعم صحة ونمو الخنازير.

شهادة

الحجم

التفاصيل

|

تصميم فتحة البطاقة، سهل التركيب |

|

حواف سميك، قوي قدرة على تحمل الأحمال |

|

|

فتحة التسرب، لا براز آمنة ونظيفة |

|

اتصال فتحة البطاقة، قوية وقوية |

|